Fabbaloo readers are most familiar with the idea of 3D printing plastic, metal or sometimes food, but how about bricks? The method of making common ceramic brick for centuries is giving way for an experiment in 3D printing building bricks.

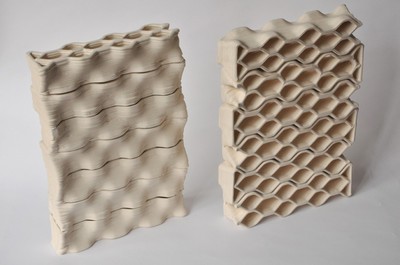

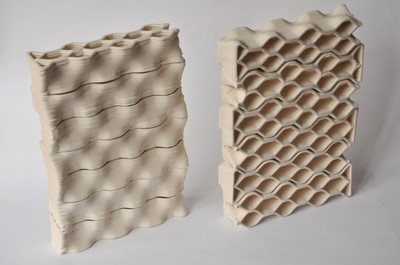

Fabbaloo readers are most familiar with the idea of 3D printing plastic, metal or sometimes food, but how about bricks? The method of making common ceramic brick for centuries is giving way for an experiment in 3D printing building bricks. The experiment is being conducted by Building Bytes, who have already designed three styles of brick prints: Interlocking, Ribbed, Honeycomb and something they call the “X-Brick”. Their method is to use a liquid ceramic air pressure-extruded from a standard personal 3D printer (which looks suspiciously similar to a BFB RapMan.)

But, you ask, why incur the lengthy delays 3D printing bricks when they can be made much faster using conventional approaches? The answer lies in the design of the bricks.

But, you ask, why incur the lengthy delays 3D printing bricks when they can be made much faster using conventional approaches? The answer lies in the design of the bricks. A 3D printed brick has far more opportunity for ingenious design than a standard rectangular brick. The printed brick could include complex exterior surfaces to permit different types of interlocking or curvature of final structure. The internal structure of the brick could be engineered to significantly lower the brick’s weight or beef up the strength required at stress points for a particular build.

Will 3D printed bricks replace conventional approaches? Definitely not, but the concept could introduce entirely new specialized brick types.

Via Building Bytes and Ponoko