Many 3D models are produced by combining and contorting basic shapes, such as cubes, spheres and cylinders, or by distorting a mesh by pushing and pulling vertices. Highly complex objects are quite possible, but laborious to produce. In other words, they’re rarely attempted by most 3D printer operators.

Many 3D models are produced by combining and contorting basic shapes, such as cubes, spheres and cylinders, or by distorting a mesh by pushing and pulling vertices. Highly complex objects are quite possible, but laborious to produce. In other words, they’re rarely attempted by most 3D printer operators. But now there may be a way to produce a particular kind of 3D feature that may prove very useful for 3D printing: the “Stitch Mesh”.

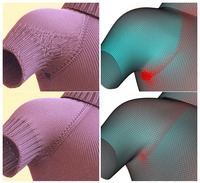

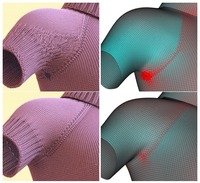

Doug L. James and Steve Marschner, the “Stitch Meshes for Modeling Knitted Clothing with Yarn-level Detail” paper is a tour-de-force examination of how to produce 3D models of knitted garments. They’ve examined the world of knitting and transformed traditional concepts into usable mathematical models capable of generating a wide variety of stitch patterns.

Using their technology, it should be possible to enable 3D modeling software to automatically wrap 3D models with highly realistic knitted fabrics. The rendered visuals are startling, and one’s mind reels with the possibilities.

Once 3D models are created in software, they can potentially be 3D printed. While an attractive concept, we see potential issues:

- Slicing such a 3D model for printing may be computationally difficult. Imagine all the curves to analyze on a full-size knitted surface. Slicing may take an enormous amount of time or even crash less robust slicing software. In fact, the authors report the elapsed time to generate several of their models, the longest duration being 33 hours! Wait, it gets worse: the generation was done on a dual Intel Xeon X5690 CPU @ 3.46 GHz with 48 GB RAM. Not exactly your typical home machine.

- The resolution of a given 3D printer may not be sufficient to resolve the fine details of a stitch mesh. In other words, all that computation may not result in anything other than a roughly textured print surface.

Regardless of such potential problems, we predict 3D printed sweaters will be forthcoming.

Via Cem Yuksel

That's really cool. I could see this software being widely used in the fashion industry. You really could get a great idea of how something would look on a person or sheep as you photo demonstration. You could then play with the pattern before you have them produced. Interesting.

That's really cool. I could see this software being widely used in the fashion industry. You really could get a great idea of how something would look on a person or sheep as you photo demonstration. You could then play with the pattern before you have them produced. Interesting.