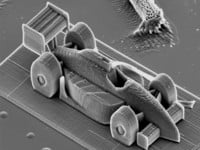

Numerous readers pointed us to a post by the Vienna University of Technology who recently made a very significant breakthrough in microscopic 3D printing. What is this breakthrough? They were able to successfully perform actual 3D printing operations at a microscopic scale, building the racing car you see in the image here.

Numerous readers pointed us to a post by the Vienna University of Technology who recently made a very significant breakthrough in microscopic 3D printing. What is this breakthrough? They were able to successfully perform actual 3D printing operations at a microscopic scale, building the racing car you see in the image here. How “microscopic” are we talking about? Consider that the racing car is only 285 micrometres long. That’s 285 millionths of a metre! We’d take a wild guess and say their 3D printing resolution is something close to 1-2 micrometres or so, based on the layering in the image. Hold on, let’s put that into perspective. A typical home 3D printer’s maximum resolution would be 0.125 mm but many people print at 0.5 mm. This experiment appears to be around 0.001 mm resolution (1 micrometre), ten to fifty times better.

It’s not just the resolution that’s revolutionary. They’ve also developed a unique method of forming 3D objects not seen before. While they use curable resin as their build material as many other commercial 3D printers do, they have overcome a significant barrier: conventional resin 3D printers can only cure the top surface of the resin pool. The new method permits a laser to penetrate deep into a reservoir and solidify submerged elements. Why is this so important? Because it eliminates the need to wash fresh resin over the build for each layer. The laser can then scoot around the reservoir in a 3D path to build the object as fast as the laser can move. And it can move very, very quickly as it’s controlled by mirrors. Apparently their technique can cure up to 5 metres per second!

High speed and super-fine resolution – a great combination. Hopefully we’ll see this technology emerge in an affordable form soon.

Via The University of Vienna (Hat tip to Charlie, Tom and many others)