Whoa – 3D printing plastic AND metal at the same time? There are many kinds of 3D printers in the world these days, most printing only plastic and some able to print metal. But printing both? That’s exactly what a joint initiative between ABS plastic 3D printer manufacturer Stratasys is doing with metal 3D printer manufacturer Optomec.

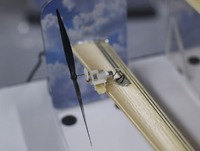

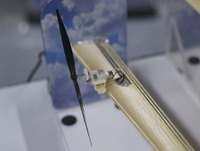

Whoa – 3D printing plastic AND metal at the same time? There are many kinds of 3D printers in the world these days, most printing only plastic and some able to print metal. But printing both? That’s exactly what a joint initiative between ABS plastic 3D printer manufacturer Stratasys is doing with metal 3D printer manufacturer Optomec. According to a story in PCMAG, the two companies have produced something “between a proof of concept and a joint business initiative”, which sounds like they have something working pretty well. The test object for this project was the wing of a UAV containing both plastic and metal elements (see image above).

How does this work? It’s actually less impressive technically than it might sound. Evidently the plastic part is printed first at Stratsys’ facilities and then it is shipped to an Optomec facility where the metal bits are printed directly onto the plastic part. The result is a hybrid plastic-metal object that was actually produced in two different 3D printers.

Not quite the breakthrough we expected, but from a client point of view they push “Print” and get back a plastic and metal object as if it came from a single 3D printer. Instead it’s essentially coming from a single 3D print service.

Small steps, progress is achieved.

Via PCMAG