Maker Zaggo has discovered a truly useful design tip for 3D models. The new design helps overcome a deficiency in many low-cost 3D printers: no support material. Support material is typically extruded from a second print head during the print to add support for overhangs and difficult object geometries. The support material is then removed after printing to reveal the complete object.

Maker Zaggo has discovered a truly useful design tip for 3D models. The new design helps overcome a deficiency in many low-cost 3D printers: no support material. Support material is typically extruded from a second print head during the print to add support for overhangs and difficult object geometries. The support material is then removed after printing to reveal the complete object. The problem is that many low-cost 3D printers do not offer a support capability. As such, 3D designs must account for this deficiency by eliminating overhangs & single tower shapes and re-orienting the object.

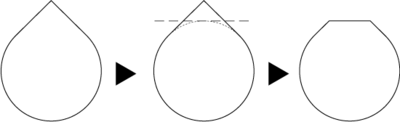

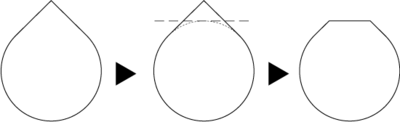

One persistent problem is the ability to print holes, where by definition there must be an overhang at the top of the hole. The standard solution has been to print a teardrop shape that reduces the overhang. Unfortunately, the standard teardrop shape does occupy quite a bit of space and thus might not be usable on some designs.

Zaggo’s innovation is to chop off the pointy part of the teardrop. This re-creates an overhang, but it’s actually ok because most modern low-cost 3D printers can actually handle short overhangs if they “bridge” to another side. The new design takes advantage of this bridging capability.

If you’re interested in trying this new shape, check out Zaggo’s post on the Pleasant Hardware blog, where he includes the OpenSCAD code to make it. You may also be interested in trying his very useful Pleasant3D software for 3D model manipulation.