We’ve seen a series of experimental personal 3D printers emerge over the past year, some on the KickStarter online funding service. Each experiment has an interesting idea that improves on the ideas of others, gradually moving the state of the art forward.

We’ve seen a series of experimental personal 3D printers emerge over the past year, some on the KickStarter online funding service. Each experiment has an interesting idea that improves on the ideas of others, gradually moving the state of the art forward. Printrbot, made by builder Brook Drumm, includes some very interesting features, not the least of which is simplified assembly. Drumm, like many of us, built his own 3D printer from a kit but found that it took many hours of work to get it done. We believe, as he seems to, that such effort simply will not be undertaken by the majority of consumers. The result is that few consumers will ever operate a 3D printer of their own.

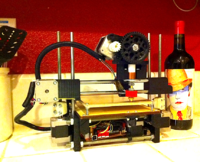

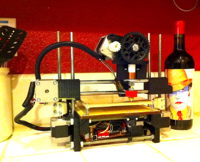

However, Printrbot hopes to change that by vastly simplifying the assembly process. The design (seen in the above image, click for more detail) is visibly simpler than the RepRaps, MakerBots and RapMans we’ve seen before. This simplification carries through into the assembly process, which Drumm claims to be as little as 45 minutes!

The design is flexible. Evidently you can add length to any of the XYZ axes, creating a potentially large build envelope. You can also add a case or perhaps even a heated build platform.

We’re quite impressed with Drumm’s design – and apparently many others are as well, since the project has already exceeded its original funding goal of USD$25,000 by more than a factor of TEN! Hundreds of kits and assembled Printrbots have been ordered, likely keeping Drumm and his crew busy for quite a while.

Via KickStarter