Our rant regarding STL the other day provoked some interest from the not-yet-well-known company Uformia of Norway. While we all agree that there are serious problems with STL format, some are starting to do something about it. One group with an interesting approach is Uformia, who are developing a new approach to 3D modeling specifically designed to work well with 3D printing.

Our rant regarding STL the other day provoked some interest from the not-yet-well-known company Uformia of Norway. While we all agree that there are serious problems with STL format, some are starting to do something about it. One group with an interesting approach is Uformia, who are developing a new approach to 3D modeling specifically designed to work well with 3D printing. We spoke with Turlif Vilbrandt, Founder and Chief Technical Officer of Uformia to ask about their product, Symvol™ for Rhino – Maker.

Fabbaloo: What led you to develop this plug-in?

Turlif Vilbrandt: Our technology comes from over 20 years of research and development, trying to answer the fundamental question: how do you accurately represent reality in a computer (and get it back out again – i.e. additive manufacturing). To illustrate the depth of this problem and the limited solutions that exist today for modeling *real* objects, you can ask yourself a simple question: “In what modeling package today can I model/design a Venetian vase with all the material (and color definitions required) to truly capture even the basic information required to truly understand it?” The answer of course excludes nearly, if not all existing consumer software as it is all based on the modeling of boundaries or 2.5D (i.e. 2D surfaces bent in 3D space with texture maps applied) and tells you nothing about the whole or inside of the object. Of course the design and modeling of a Venetian vase is a very simple example compared to an object from nature such as a human heart. The very basis of modeling a 3D+ world in 2D surface is fundamentally an incorrect starting point. Our platform models all objects as true 3D volumes and can include the definition of any number of properties (such as material or color) anywhere in the volume – including the blending of those properties.

Fabbaloo: What problem are you solving?

Turlif Vilbrandt: Symvol™ for Rhino – Maker Version BETA represents the beta version of our first, “hello world” modeling tool, which offers an introduction to real volumetric modeling (Maker has a limited subset of functionality – for example it does not include the modeling of properties). We are not a voxel modeler or a blob-modeler, or a CSG modeler, or surface modeler (however our underlying platform can convert meshs and voxels).

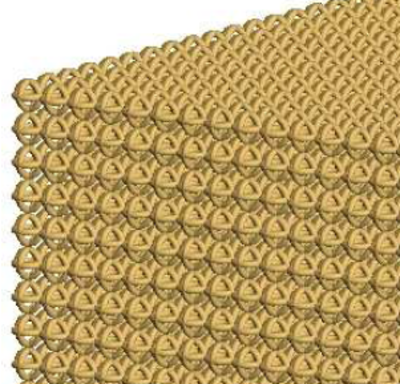

In addition to a host of advantages over other 3D modeling approaches, any object in our system, no matter the complexity, is inherently watertight. This of course is well-suited for 3DP and similar to CSG (FYI – true CSG is actually 3D and can be seen as a subset of our approach) as discussed your post “An End To The Dreaded STL Format?” from 2 days ago, can slice and send data directly to 3D printers (which Maker can do now). Currently 3D printers are not being used in many cases at their full resolution and capabilities only due to STL and the current modeling software limitations. See these images for an example of a simple microstructure that STL for example has a lot of trouble with.

Note that this structure has no flat surfaces – it is a continuous perfect surface that can be sent to any 3D printer at its maximum or near maximum resolution from Maker.

Fabbaloo: Why the focus on 3DP?

Turlif Vilbrandt: Looking a bit further, one can see the elusive “3D print button” (that even grandmother can use) is possible, but not while we are are all still using 2.5D – so keep your eye on Maker.

As with most things, there is more than meets the eye. In this case, we must begin to think about what happens inside our printed objects – the part we can’t see.

Via Uformia (Hat tip to Cherie)