Charles R. Goulding and Preeti Sulibhavi examine Mexico overtaking China as the top trade partner of the U.S. and how it can spur 3D printing’s potential.

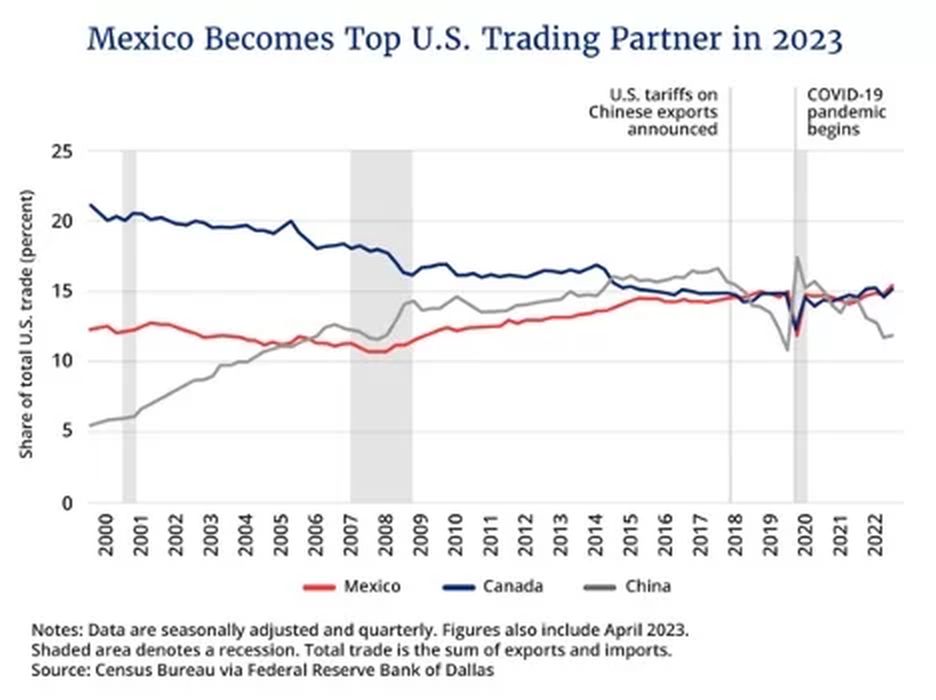

A major shift occurred in 2022 that is important for companies in the 3D printing industry to take note of. According to data from the U.S. Census Bureau, Mexico has now surpassed China as the United States’ largest trading partner for imported goods. Total imports from Mexico reached US$380.7 billion in the first 11 months of 2022, topping China’s US$352.4 billion. This represents an 18.1% increase in imports from Mexico compared to the same period in 2021.

China had held the top spot since 2015, but supply chain issues and production shutdowns related to China’s zero-COVID policy opened the door for Mexico’s rise to number one. Additionally, nearshoring efforts have boosted manufacturing capacities south of the border. With lower transportation costs and quicker delivery times, many American companies are finding it advantageous to import more goods from Mexico rather than overseas.

As the leading importer of U.S. goods, Mexico offers substantial opportunities for expansion that 3D printing companies should tap into. Below are four examples of firms already leveraging 3D printing capabilities in Mexico across various industries:

- Axolotl Biosciences – This startup focuses on regenerative medicine and tissue engineering. Using 3D bioprinting technology, they aim to print living tissues and organs for research and transplantation. The Mexican-origin company has operations in both Mexico and the United States.

- Idinsa – A leader in digital manufacturing headquartered in Mexico City. They offer industrial-grade 3D printing services for sectors like aerospace, automotive, medical, and consumer products. Services range from 3D scanning and modeling to selecting materials/technologies and producing final parts.

- Mobility3D – A Monterrey-based provider of 3D printed mobility devices specifically for the rehab market. Their devices are custom-fit and lightweight, including advanced prosthetics and orthotics. They collaborate with physiotherapists and doctors to scan patients and identify needs.

- Zua Robotics – This startup focuses on Mexico’s housing shortage with 3D printing. They use concrete 3D printing techniques to construct affordable homes quickly. Homes can be customized via digital models and printed on-site by their specialized equipment. The streamlined process reduces labor costs and builds homes 60% faster compared to traditional methods.

As these examples demonstrate, 3D printing can serve a wide range of manufacturing and medical needs in Mexico. With the country now being the lead exporter to the U.S., there is set to be increased output across sectors leveraging digital technologies. Everything from consumer goods and commercial supplies to precision medical devices and industrial components.

For 3D printing companies, establishing or expanding operations in Mexico can aid domestic capabilities while also being close to their largest external market. Some key advantages include:

- Cost Savings – Labor, materials, logistics and other costs can be lower compared to operating solely in the U.S. Allowing companies to be more competitive.

- Access to Talent – Mexico has a large, skilled workforce to hire locally for specialized technical and engineering roles.

- Geographic Proximity – With a shared border near major U.S. hubs, parts/products reach their destination faster at lower shipping expenses.

- Trade Incentives – There are financial incentives and government support programs to spur innovation sectors like 3D printing.

The Research & Development Tax Credit

The now permanent Research and Development (R&D) Tax Credit is available for companies developing new or improved products, processes and/or software.

3D printing can help boost a company’s R&D Tax Credits. Wages for technical employees creating, testing and revising 3D printed prototypes can be included as a percentage of eligible time spent for the R&D Tax Credit. Similarly, when used as a method of improving a process, time spent integrating 3D printing hardware and software counts as an eligible activity. Lastly, when used for modeling and preproduction, the costs of filaments consumed during the development process may also be recovered.

Whether it is used for creating and testing prototypes or for final production, 3D printing is a great indicator that R&D Credit eligible activities are taking place. Companies implementing this technology at any point should consider taking advantage of R&D Tax Credits.

Conclusion

With Mexico rising as America’s most crucial trade ally, there are compelling reasons for players in the 3D printing industry to have an established footprint serving this bustling market. Expect continued momentum in coming years as companies leverage Mexico’s capabilities – from cost-effective production and specialized talent to proximity delivering goods to the U.S. quickly and affordably. Tapping into Mexico’s expansive manufacturing ecosystem can fuel 3D printing’s burgeoning future.