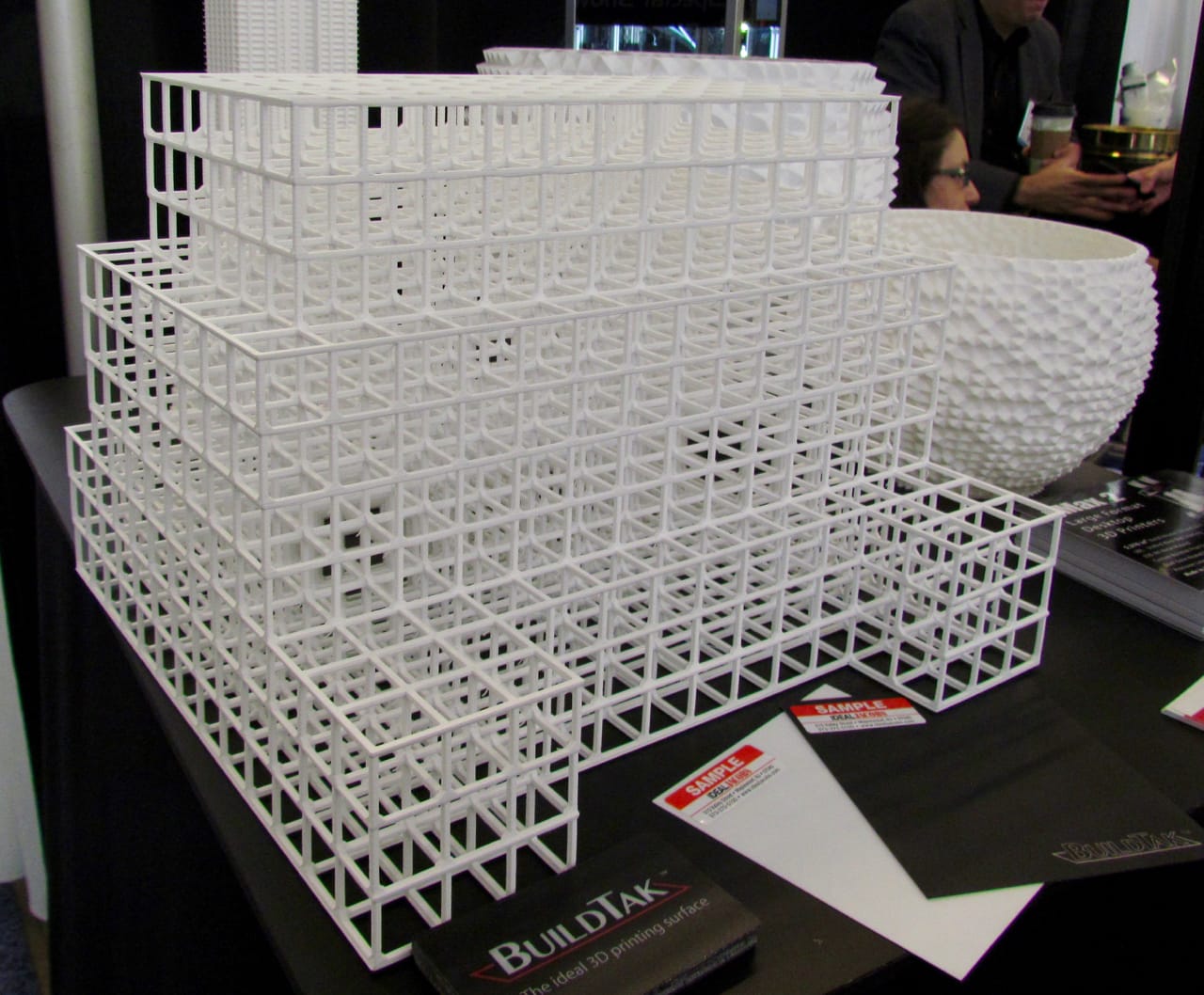

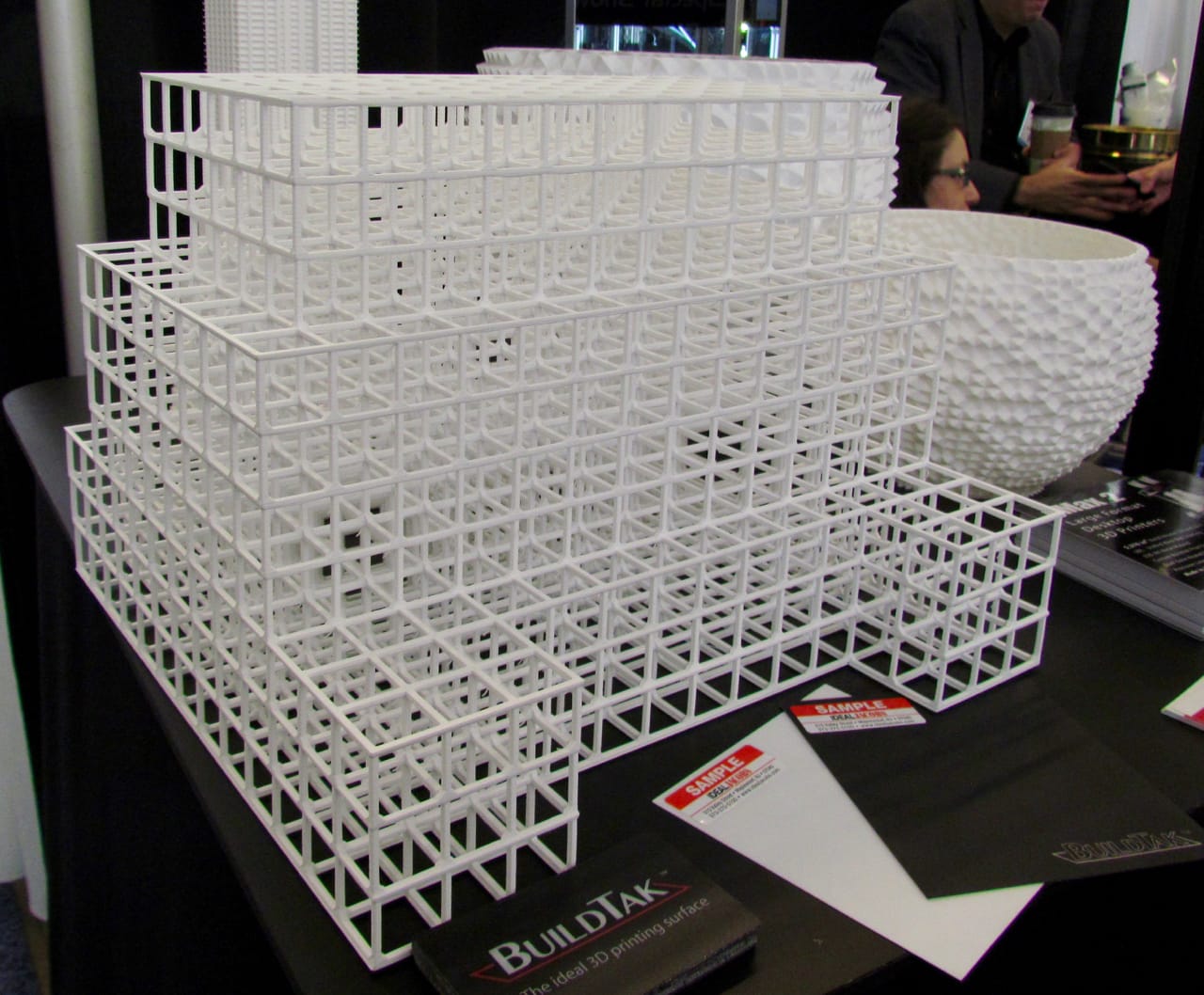

This week’s selection is the amazing “Ultimate Bridge Test” by Gordon Laplante.

This seemingly impossible-to-print 3D model was developed by Gordon Laplante of Brookly-based gCreate, a manufacturer of larger format desktop 3D printers. The model was created as a means of demonstrating the ability of their 3D printers to successfully execute a ridiculous number of bridges.

In a “bridge” scenario, the 3D printer must successfully pull a soft extrusion across a short gap with just enough force to form a straight line.

The tension of the moving hot end should be sufficient to keep it straight, but if the 3D printer is tuned incorrectly, you’ll often see a sag on the bottom strands.

There are no sags on this print.

And that’s pretty amazing because this 3D model has literally hundreds of bridges, each successfully executed. The 3D model has definitely proven the ability of gCreate’s equipment.

The print is actually unfinished, as it actually extends a bit taller, but I think the point was made on bridging.

As far as I can tell, gCreate has not released this 3D model to the public. It would be very interesting to see the results on other equipment.

It’s possible other equipment can also print this successfully, so long as the machine is properly tuned for the filament being used and this particular 3D model. But it’s clearly a challenge to print in any case.

Laplante explained that a future version of this 3D model may be developed to include larger “cubes” on the outside and tighter ones towards the interior to enable one to see further into the structure. As it is, seeing through it is quite difficult unless it is perfectly lined up.

Via gCreate