Recently we spoke with representatives from Verbatim and found out about some new filaments they are working on.

Verbatim is a household brand to be sure, but did you know they also produce a line of very high quality 3D printer filaments? Verbatim is actually a brand of Japanese giant Mitsubishi, who hold an enormous number of patents on specific plastics compositions, which they intend on marketing through their Verbatim brand. I wrote some thoughts on how their entry to the market could disrupt things a while ago.

I’ve tested some of their products, including the wonderful, but strangely named PrimAlloy, which is a flexible filament. It’s easily printable at good speeds on almost any 3D printer and has proven in my experiments to be quite reliable.

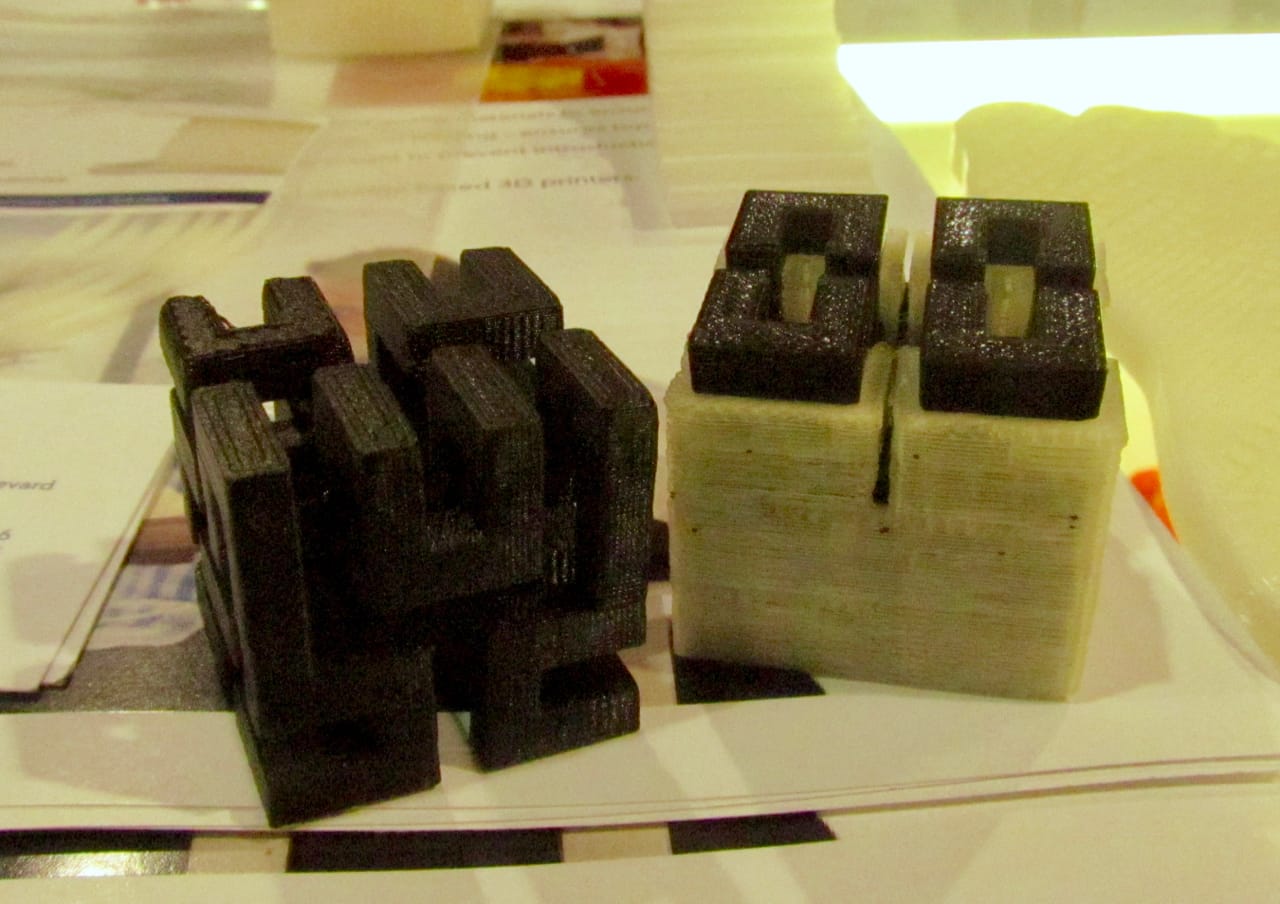

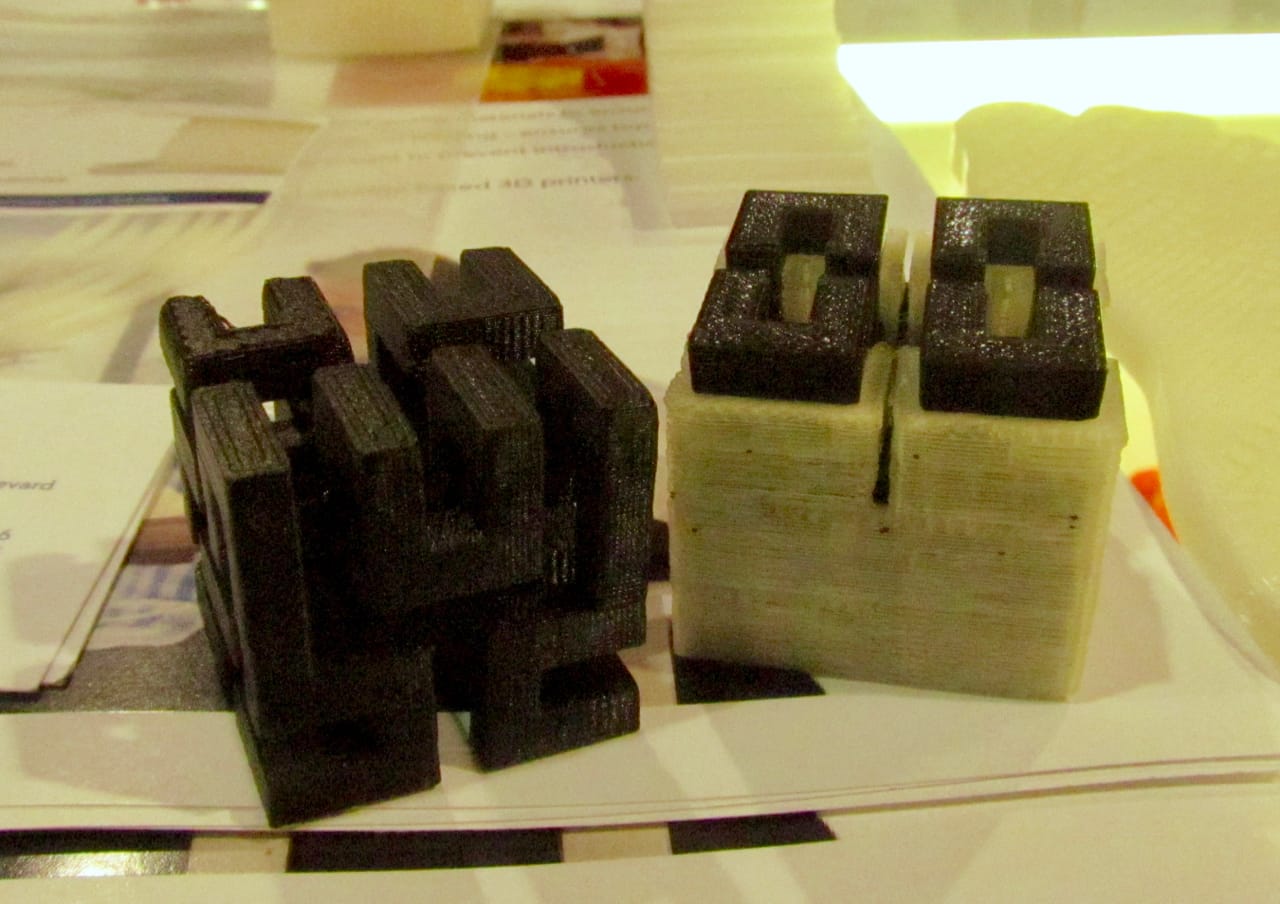

But now I see they are working on two new filaments. One is BVOH, a water soluble material. We’ve seen this type of material before from others, as it is increasingly popular. The idea is that you use it as a support material for very complex geometric objects. Then instead of picking or snipping off the support material when the print is complete, you simply dunk it in a liquid to dissolve the support. This makes 3D printing of any shape vastly simpler to accomplish.

The other new material from Verbatim is a polypropylene filament, again not particularly unique, but still a bit rare in the shelves of 3D printing filament providers. This is an emerging 3D print engineering material that some designers are seeking for particular applications.

I’m told Verbatim is looking for distributors for their products, so filament resellers, take note!

Why I find this interesting is that these two materials in particular support the growing trend towards professional desktop 3D printers, a kind of new emerging class of equipment that’s beyond the early consumer and hobby desktops, but far less expensive than traditional industrial 3D printing gear.

It seems that there is a market niche growing for this style of equipment, where it can be used directly by engineers, designers, architects and other professionals for profitable purposes.

This niche has been addressed by several 3D printer manufacturers, many of which we’ve written about. These include machines with industrial-quality components and the ability to 3D print in a far wider set of materials.

But can a niche survive and grow if it doesn’t have a complete ecosystem? I think not.

But the announcement by Verbatim that they’ve been working on materials that specifically address this niche means an ecosystem of a sort is developing. Materials need machines to print, and printers need materials to print.

Verbatim seems to be supporting that professional notion, as are a few other providers, both printer manufacturers and materials suppliers.

I suspect that this ecosystem is set to grow very strongly in the next few years, benefit both parties. And, of course, the professionals using them.

Via Verbatim