A 3D printer manufacturer has a new application target: foam!

Foam, you ask? Everyone is familiar with foam, as it’s been around for decades. Foam has been traditionally produced with a chemical reaction process: resins are mixed that produce countless small bubbles. These bubbles become fixed when the resin solidifies shortly thereafter.

Foam is incredibly useful in many applications. It is lightweight, insulative, inexpensive and provides shock-absorbing qualities. It’s commonly used for protecting more valuable components.

But there’s one problem: because it’s made from a single type of material, the entire batch takes on the same characteristics. The same chemical reaction causes the same size of bubbles throughout the resin mix.

Thus in order to meet specific design needs engineers must use different amounts of the foam, or change the type of foam produced.

But this could all change with a new software system from Carbon, makers of industrial 3D printers using their proprietary CLIP fast 3D printing technology.

They realized that foam is essentially an organic lattice structure. And they also realized that 3D printers can produce lattice structures, too, although they often don’t appear quite so organic.

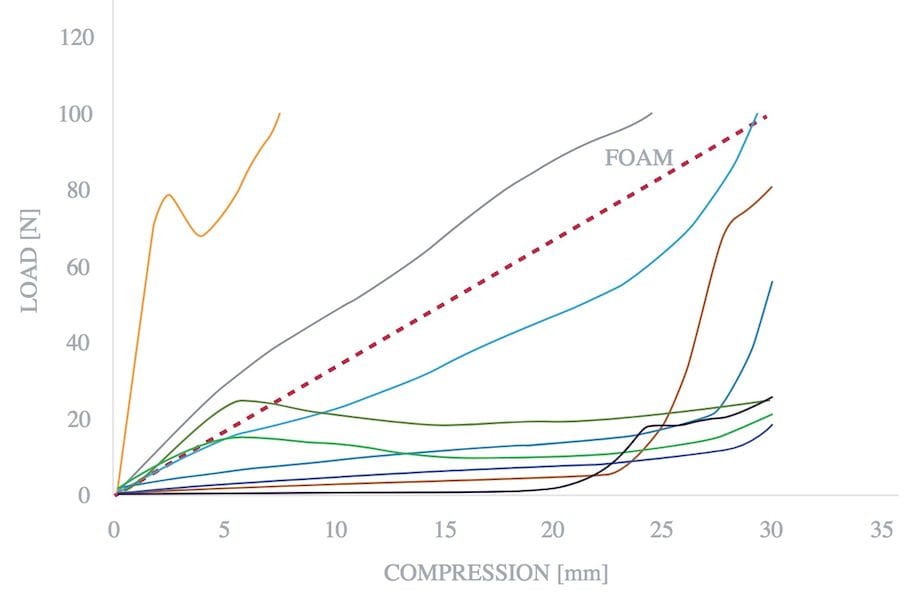

But even better, it is possible to CONTROL the nature of the lattice. You could, for example, make the lattice sparser or denser in different zones simply by adjusting the distance between the voids or thickening or thinning the lattice structures.

Carbon has apparently developed specialized software to do this precise type of 3D design. Their software includes a library of different lattice types and styles that can be tweaked and inserted into 3D design to achieve almost any foam requirement. And these “foam” prints can be made with any of Carbon’s many material types, some of which are quite a bit stronger than common traditional foams. It’s thus possible to produce a foam-performant object at a smaller size.

Carbon calls these designs “meta materials”, as they have ultimately different engineering characteristics than simply the raw material alone.

I’m excited about this development because it provides an easy path for users to achieve “impossible” designs with their 3D printing equipment, something early 3D printer operators would have found quite challenging. 3D printing is supposed to enable the creation of revolutionary new objects and that just got a little bit easier.

Via Carbon