BuildTak has become a very popular solution to hold down prints on otherwise uncooperative desktop 3D printers, but now they’ve come up with a new approach.

The new product, called the BuildTak Flexplate system, involves three separate parts:

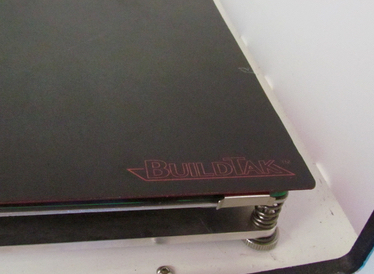

- A magnetic plate that’s permanently affixed to your build surface on the printer itself

- A flexible plate that can magnetically attach to the mag plate

- A replaceable build surface that adheres to the flexible plate

The idea here is to provide a way to very quickly remove completed prints from the printer by magnetic detach. The flexible plate is similarly important because it provides a way to easily remove prints by simply twisting the flexible plate – prints usually just pop off.

The sticky surface, which is adhered to the flexible plate, is pretty much the same BuildTak we’ve been using up to now. But instead of being attached to a rigid print surface, like glass or acrylic, it can now be flexed to remove prints. Also, the ability to replace this layer is important as BuildTak eventually loses its ability to hold prints as you repeatedly print on it. I’m told that ABS plastic tends to wear it out faster than PLA.

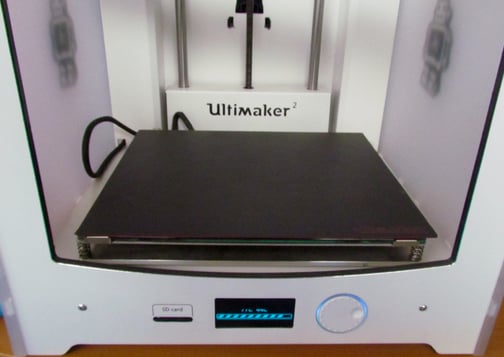

They’re expecting to release the new product in 1-2 months, at a price yet to be established. The reason for the delays has to do with the magnetic plate, which must be custom manufactured for each specific 3D printer. Here we see one that’s designed to fit exactly into an Ultimaker 3D printer, but you can imagine the number of sizes and shapes they will have to develop before they can sell them en masse. It’s not like the old BuildTak stickers that could simply be cut to size.

Via BuildTak