We had a close look at an unusual desktop 3D printer recently: the MFact from CAD2Parts.

The Istanbul-based company has been providing prototyping services for some years and now has released a new desktop 3D printer specifically for engineering use. In only one year they’ve managed to put together a device that includes several unique features.

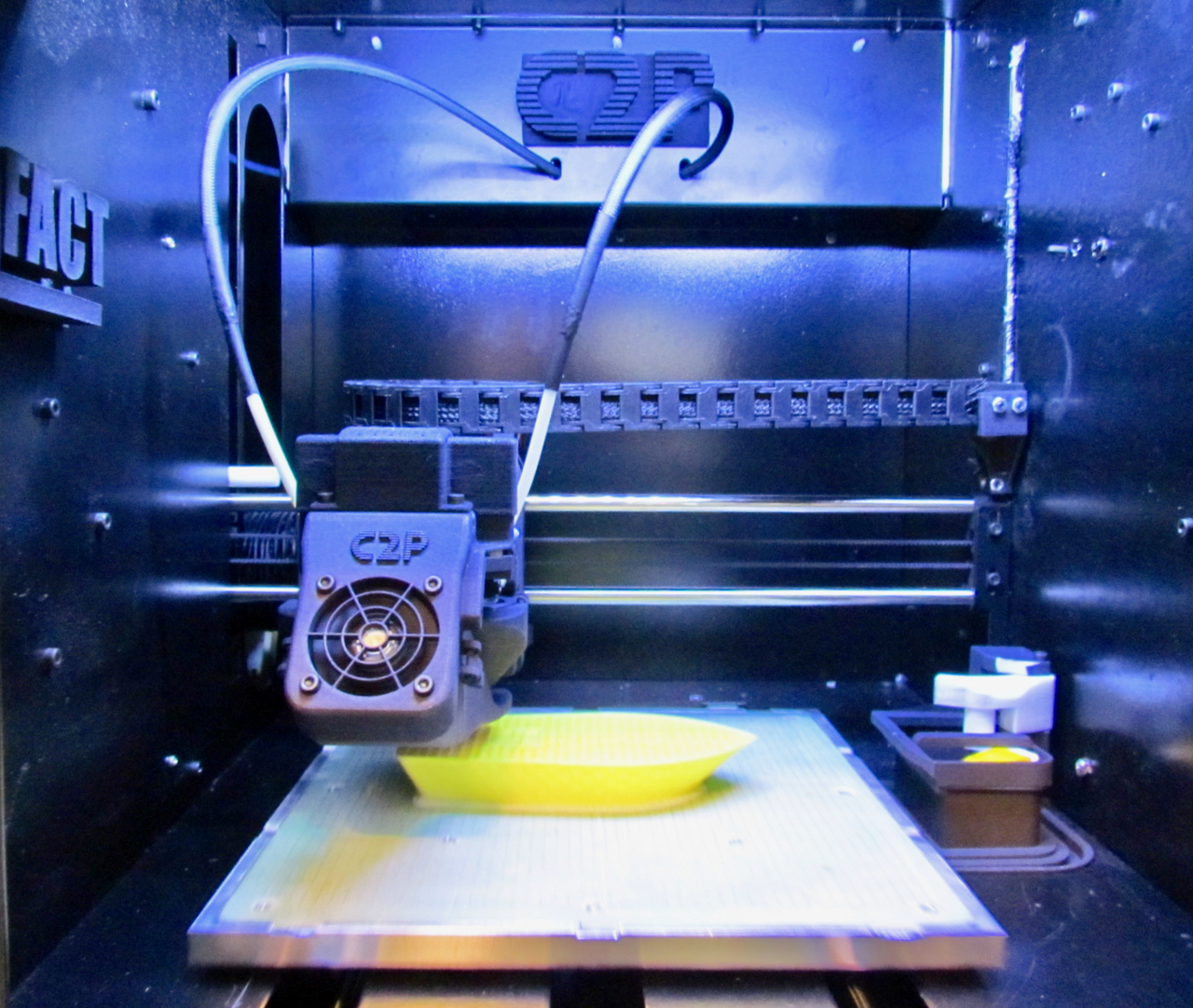

The MFact is a filament-based unit that has a generous build volume of 200 x 200 x 195mm, suitable for many prototypes.

Like many new engineering-focused desktop 3D printers that have recently emerged, this machine includes features designed to assist engineers in 3D printing reliable objects in a wide variety of materials.

The main feature of the MFact is its attention to precise heating. Through the heat generated by the heated build plate, the build chamber operates at around 55C, a high temperature that can greatly assist in ensuring accurate prints.

But one problem that sometimes occurs in this scenario is that the print head can overheat, leading to jams as plastic material flows where it shouldn’t. To do this, you must cool the portion of the print head. Frequently this is done by simply applying a fan to the area, but that is less effective when the air being blown is 55C.

To overcome this, we were told that the MFact cools the print head with outside air that’s far cooler. While that makes sense, how this is accomplished is not apparent from this view of the interior of the MFact.

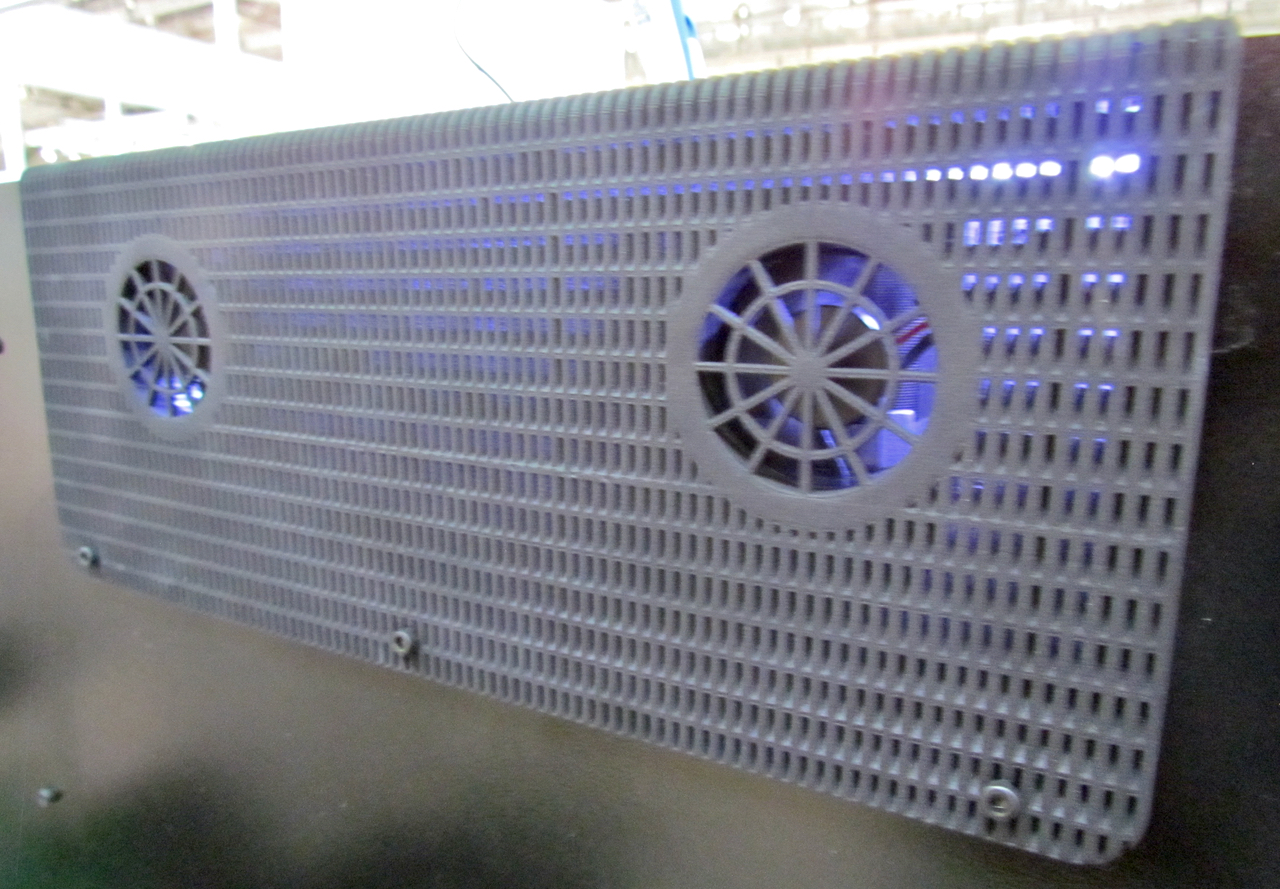

Here you can see two of several fan units attached to the MFact that are used to control the internal temperature to optimum levels.

Another unusual feature that we’re beginning to see on an increasing number of machines is the “two filaments – one nozzle” configuration, in which more reliable dual-material 3D printing can take place: there is no second nozzle to get accidentally caught up in stray plastic.

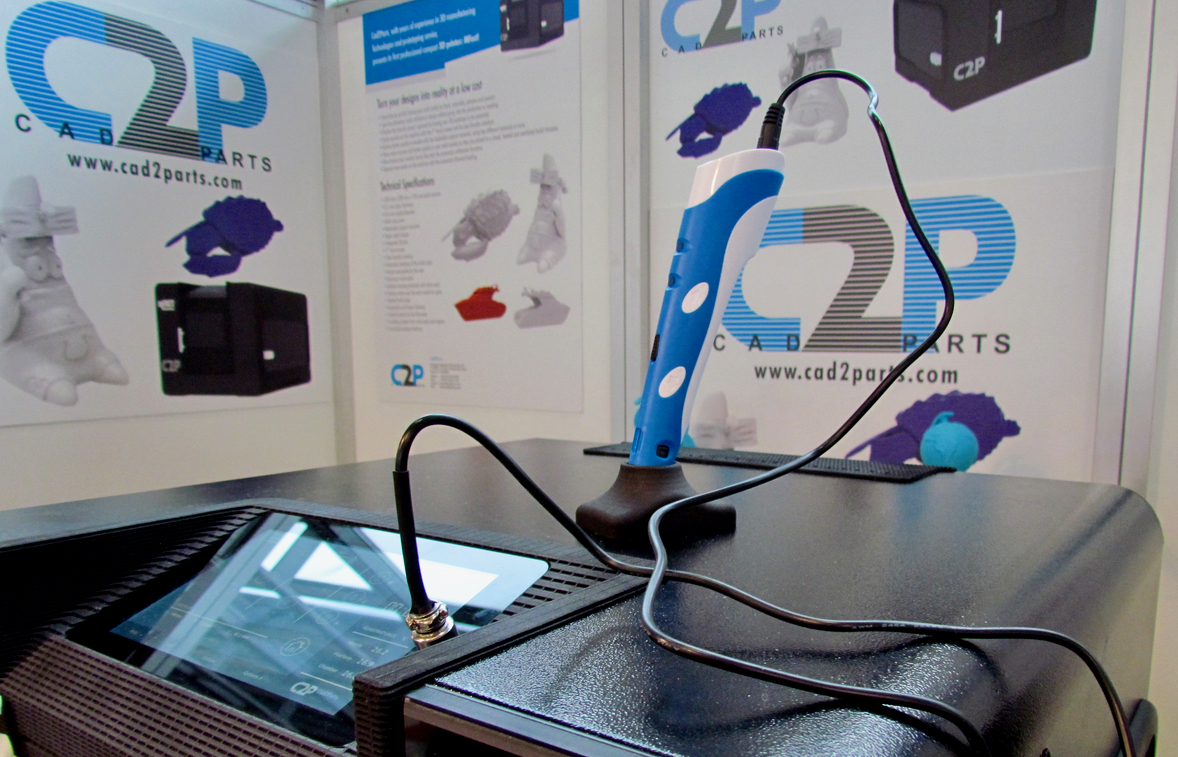

The MFact also optionally includes an integrated 3D pen that can be used for minor repairs of erroneous prints.

Each machine comes with a spare print head, and this greatly simplifies servicing: When the system fails, you swap in the spare and send the failing unit for service. No downtime!

Filament is interesting on this machine. It uses “open materials”, and no chipped cartridges are required. Thus you can use a huge variety of materials in the MFact. The machine also includes an auto-loading system and has a heated spool container, although I’m not sure why that is necessary.

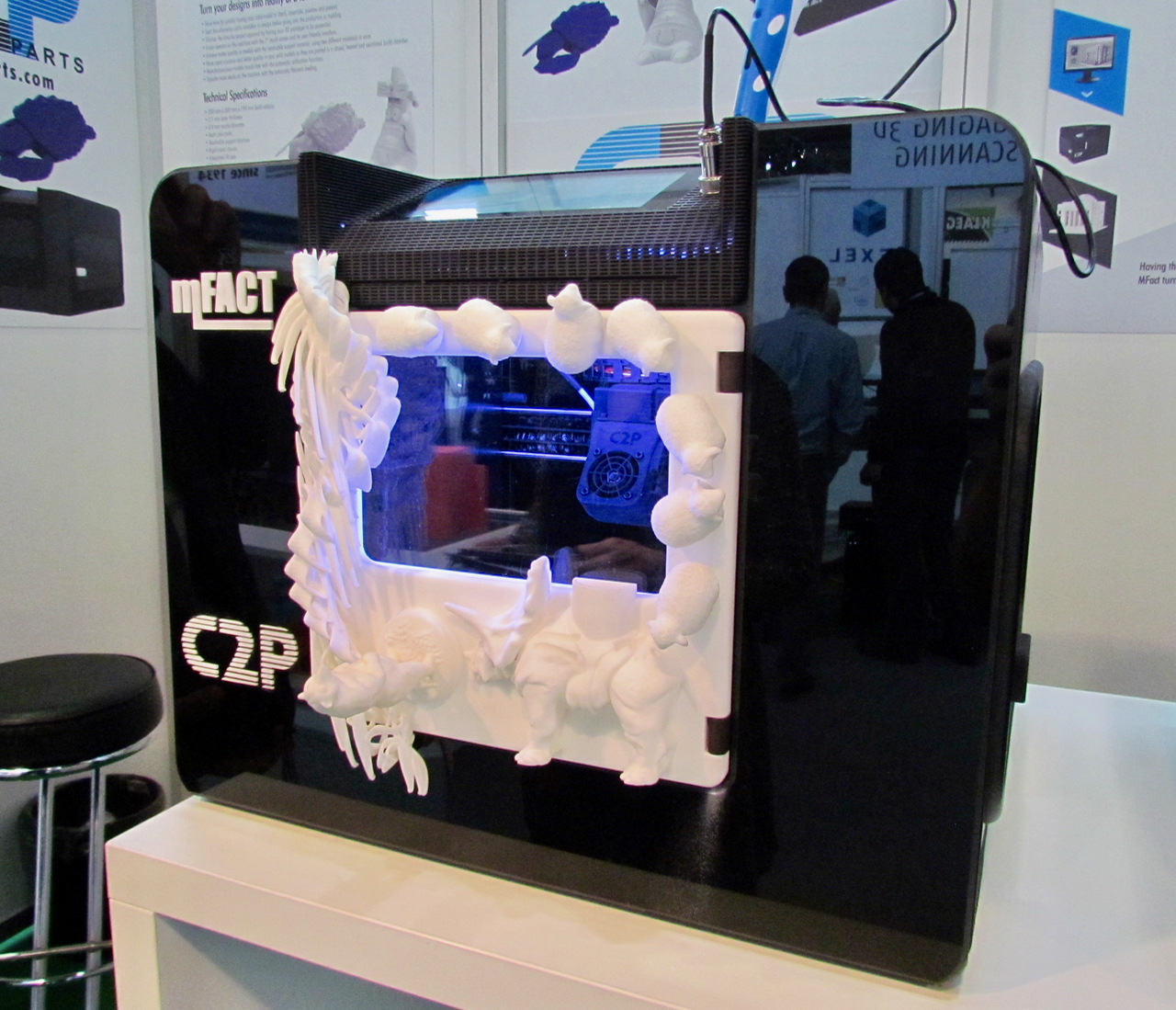

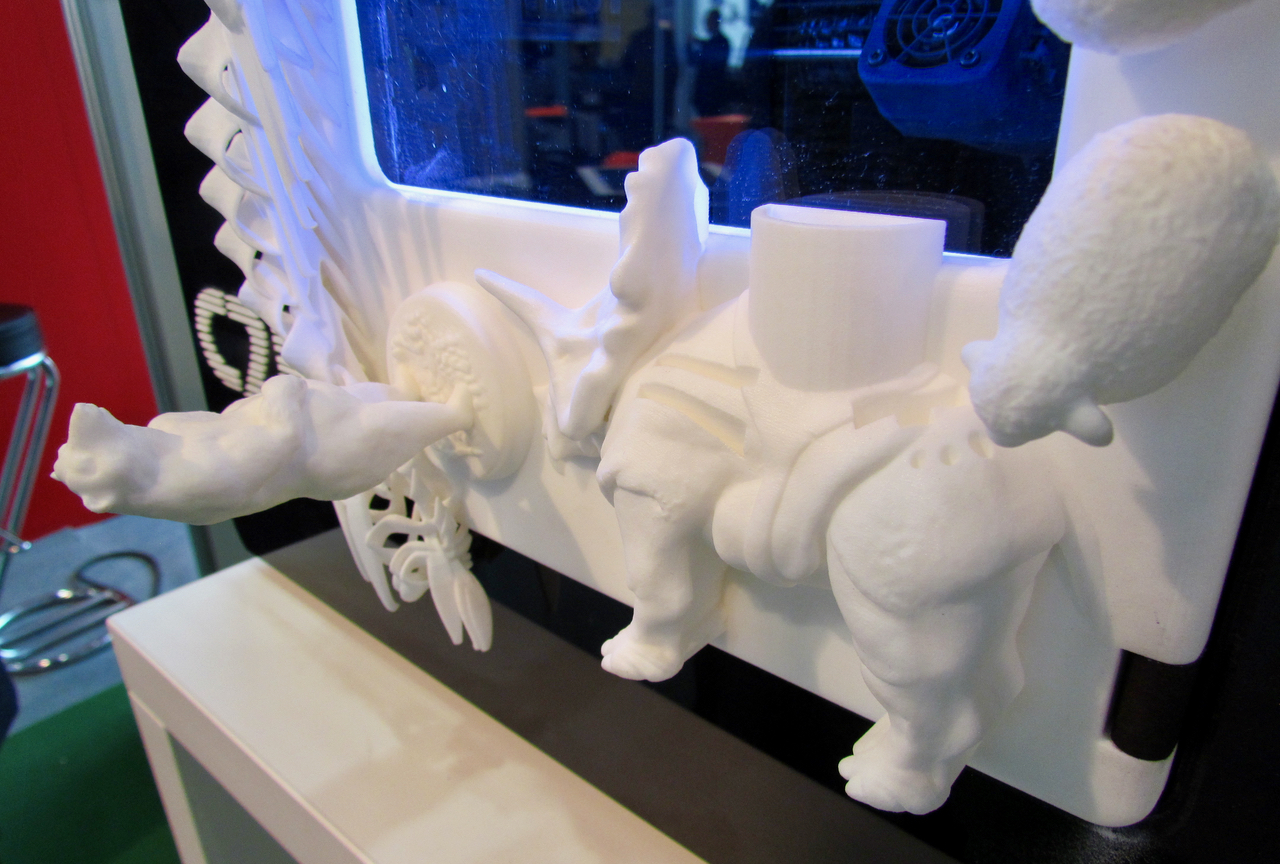

The machine also includes a fun feature: you can print decorative elements to attach to the front panel of the MFact.

Here you can see an example of such a print.

The machine is priced at USD$4,450.

Via CAD2Parts (Turkish)