We’ve been following the development of BigRep for some time now, and at this point the company is a significant player in the 3D space.

Started only a few years ago, the idea was to build a large-format 3D printer based on technology that had, at the time, only been used within smaller desktop models.

Since then the company has gradually improved their products and just last week announced their second machine. Actually, they have a third product in a way also, as they’ve partnered with Germany-based Kühling&Kühling to rebrand their massive delta-style heat-controlled 3D printer through BigRep’s globe-spanning sales and service network.

BigRep is itself now big: they boast of around 70 staff, 40 resellers and have multiple offices: Europe, North America and Asia. This globally-spaced office configuration permits them to deploy “follow the sun” support services: there’s always someone awake to provide assistance to their customers. BigRep says they are able to provide 4-hour response time all day long now.

Of most interest to me is the fact that they’ve sold over 140 systems to date. Now considering that the price of their systems is around USD$40,000, that suggests they’ve received revenue of at least USD$5-6M, with more no doubt from service and supplies sales.

While they appear to be a well-run company, they did have a significant advantage over other 3D printer startups: price margin.

Smaller 3D printers faced enormous competition from literally hundreds of vendors, quickly reducing the price they were able to sell machines to the public. With a reduction in price, margins also decreased. In extreme cases, some small 3D printers surely have profit margins of only a few dollars per machine. And yes, there are some that actually don’t make any money at all.

But in the case of BigRep, their high fee – commensurate with the large unique functionality – permitted the company cash flow sufficient to grow. They’ve attracted investors, clients and staff to build to today’s state. In fact, we were told they have recently acquired several technicians who formerly worked for Stratasys.

Today the company finds itself with customers producing unusual large items on their machinery, including a custom marine propellor factory, who can now make propellers in only three days instead of 25 days. Another client makes whole bathtubs using the system – in three pieces.

Where will BigRep go next? They’ve described a couple of very interesting initiatives to us.

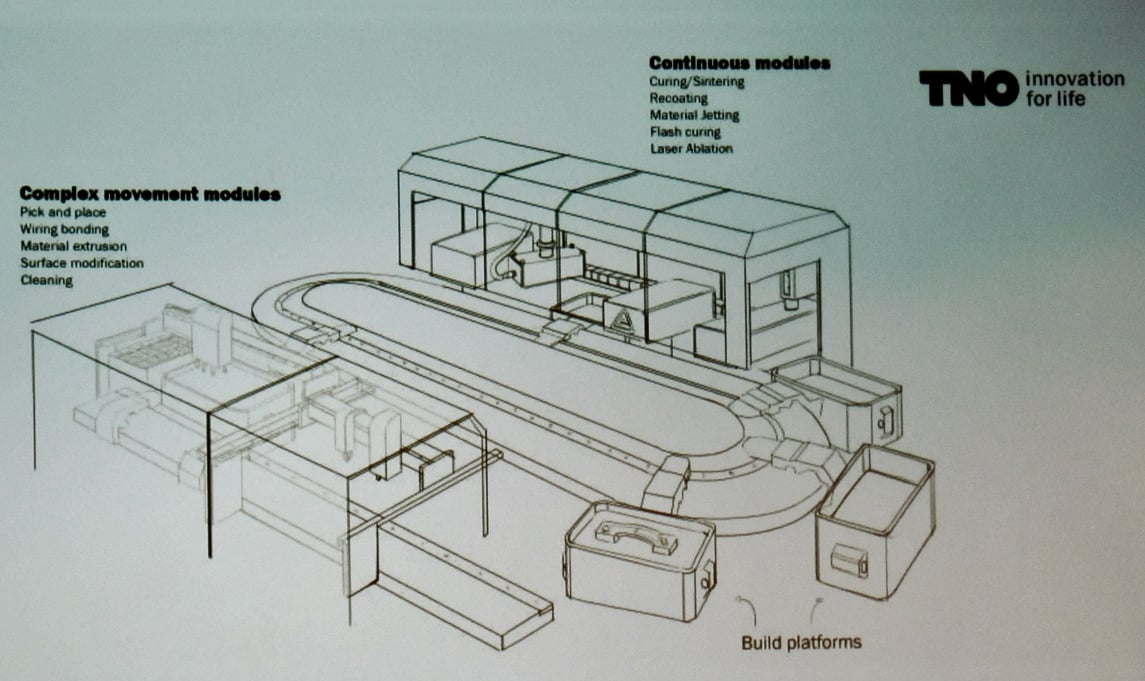

One is that they intend on partnering with TNO, a major technological research organization in the Netherlands. The idea here could be to “factoryize” their system and enable it to be used within manufacturing in a much easier manner.

In this image we can see multiple manufacturing functions mentioned, including:

Pick and place

Wiring bonding

Material extrusion

Surface modification

Cleaning

Curing/Sintering

Recoating

Material jetting

Flash curing

Laser ablation

These are not functions currently offered by BigRep, but it may be they wish to participate in such a factory system.

Another initiative they mentioned was a way to provide spare parts on demand through the use of a vision recognition system. It might be like a “Shazam for 3D printing”, where you can order a print-on-demand part once recognition takes place.

Things are certainly interesting at BigRep.

Via BigRep