At CES we examined the new Polaroid desktop 3D printer, and found a very surprising element.

The elusive 3D printer was difficult to find, as it was hidden in Polaroid’s enormous booth, located with other camera manufacturers, far away from the 3D printing zone at the event. After an hour of travel, we managed to set our eyes on the new device and speak to a representative about it.

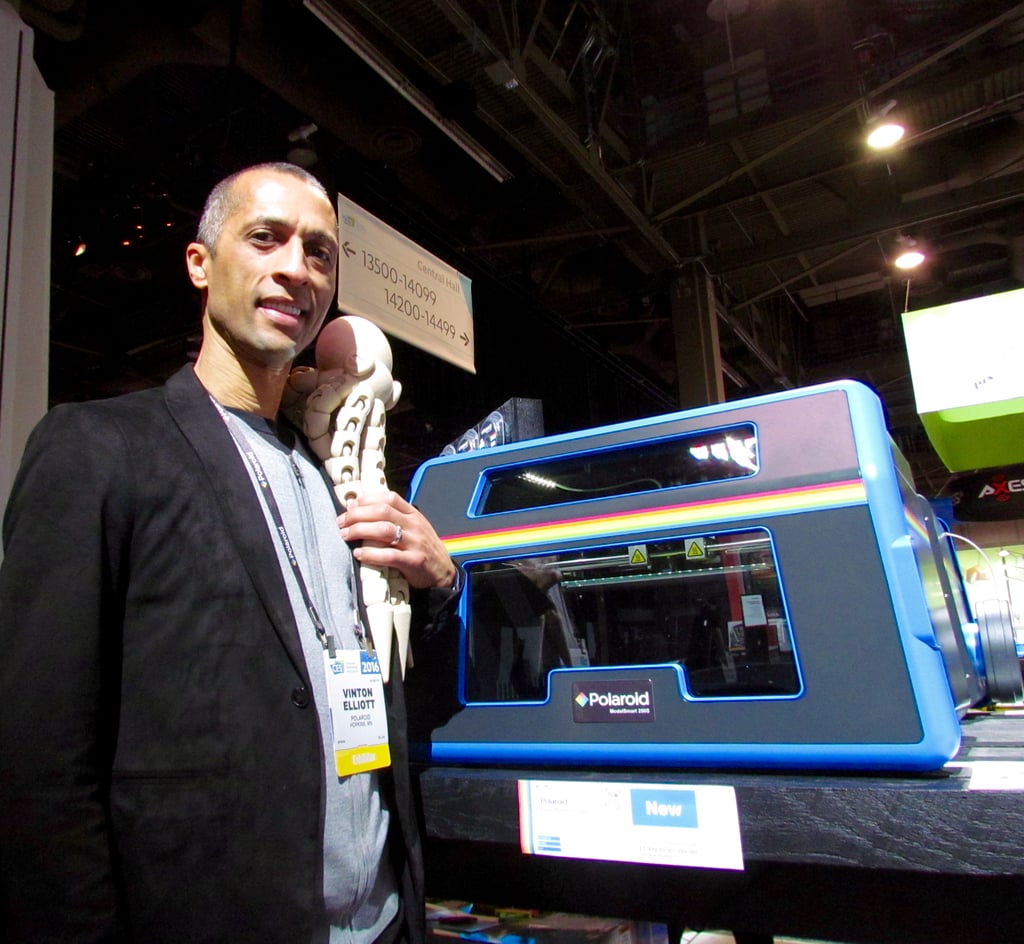

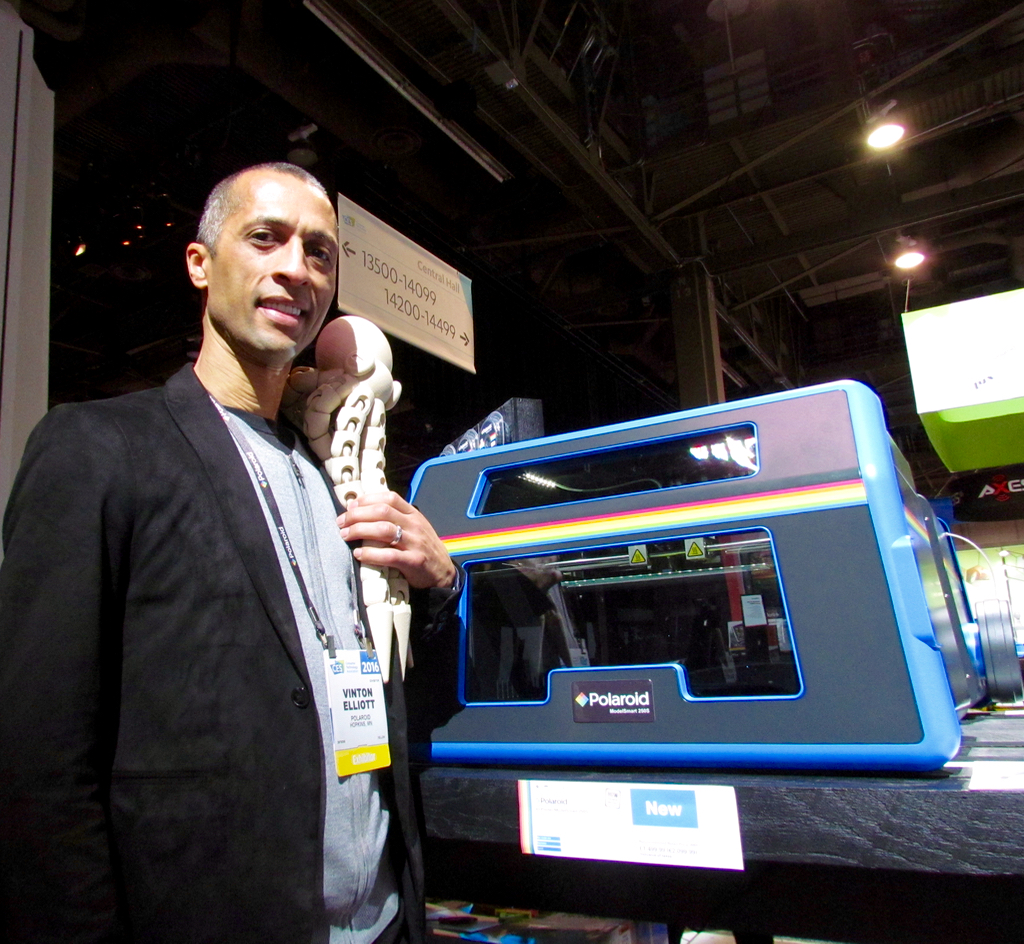

The single model 250S printer is visually noticeable, with it’s flamboyant baby-blue exterior, equipped with the Polaroid stripe. It’s also quite physically large compared to its healthy 250 x 250 x 150mm build volume. We think the case could have been made much more compact.

Essentially, this machine is a basic PLA filament 3D printer, capable of printing only PLA and PLA-variants, such as wood-filled PLA filament. The print surface is not heated, so you won’t be printing any unusual materials with this device.

Notable features include a small touch screen, easily accessed on the top of the box, a self leveling process, and a safety feature: the print automatically pauses when the door to the enclosed build chamber is opened. Filament can be swapped while paused, and the printer can resume when ready. Connectivity is provided through USB or SD card, and the printer can produce layers between 0.05mm to 0.350mm in size. Swapping the nozzle quickly is also possible by detaching two easily-accessed screws.

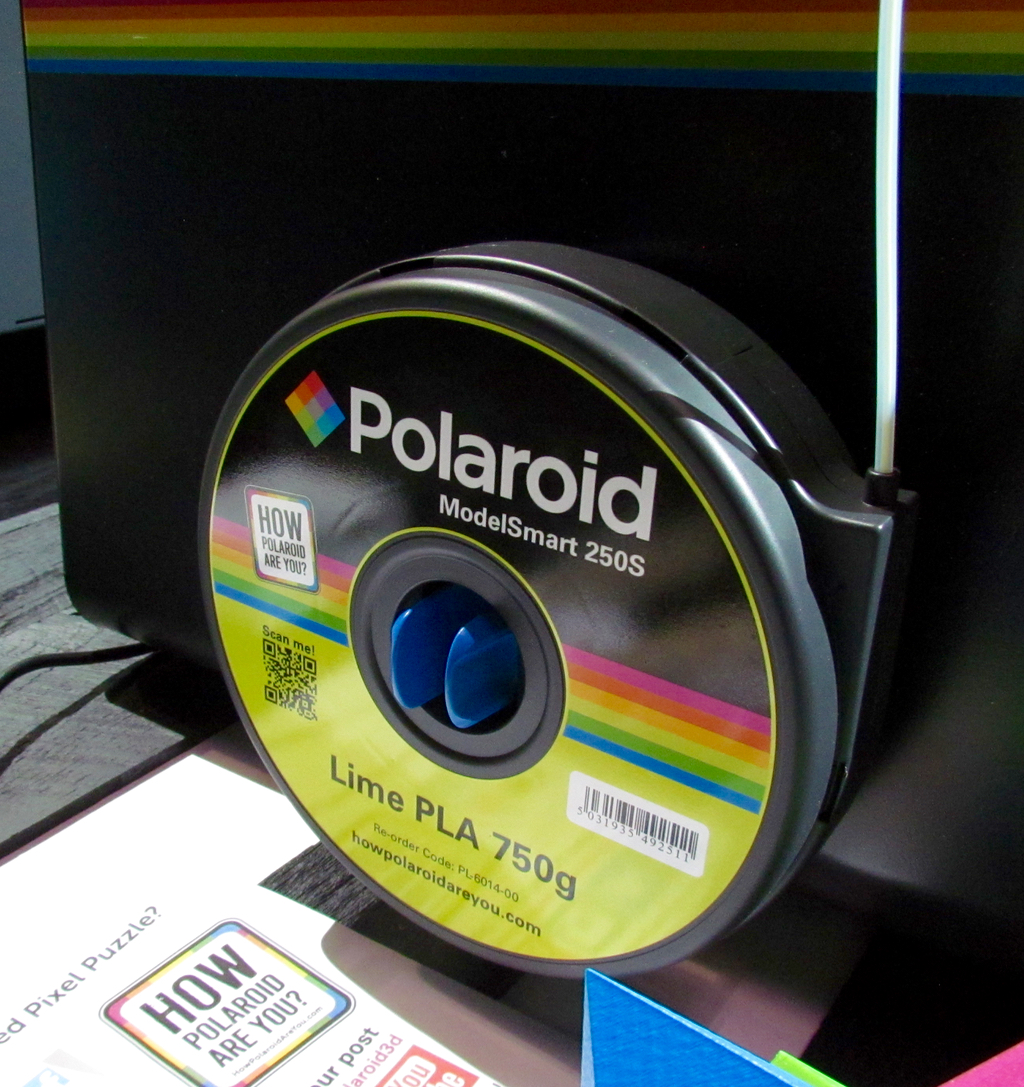

But then things get a bit strange. The 250S uses proprietary filament cartridges only. These Polaroid-branded spools are controlled by chips and contain 750g of material. The problem is that these spools will set you back USD$100 each, far higher than the going rate for plastic filament. Today you can get a kg of reasonable filament for USD$20, making this spool almost seven times more expensive to use than generic filament. At this time, they’re offering nine different filament colors and a wood filament.

But that’s not all! The 250S’s print surface is not heated, so we asked how adhesion is accomplished. It turns out that you must apply a special double-sided adhesive sheet to the print bed – ON EVERY PRINT! In other words, every print requires a new sheet, even if the print fails. The price of the sheets was said to be USD$30 per 15 sheets, or about USD$2 per print!

We have never seen this style of consumable pricing on any 3D printer with the exception of the very high-end Stratasys industrial 3D printers.

There is dedicated software for the 250S, which provides the usual printer management functions. However, the software also connects directly with the machine to monitor consumable levels and can interact with local resellers of required consumables. Automatic ordering? Perhaps.

The printer is not manufactured by Polaroid, but is a 3-year collaboration between Polaroid and UK manufacturer Environmental Business Products (EBP), a provider of inkjet recycling products. Evidently EBP began development of this machine 18 months ago, and now it’s almost ready for deployment.

The machine is not yet available, but you can pre-order units online now, with shipping expected in March. Pricing for the 250S is set at a rather high £1,499.99 / €2,099.99 (USD$2,250). Sales through Polaroid’s huge reseller network is expected to follow.

Via Polaroid