Remember Lumi Industries? They developed the Lumifold compact resin 3D printer. Now they’re working on something even stranger: a 3D printer concept that uses a tablet.

Their fundamental development is in a new form of Z-motion system that could potentially be used in many types of 3D printers. It seems to be a pair of scissor mechanisms that hold up – and move – a platform. They call it the “New LumiFold”.

The benefit of this approach is that the scissor mechanism is quite small and can be folded down to save space. One can imagine a 3D printer that collapses down into a thin footprint the size of the printer width.

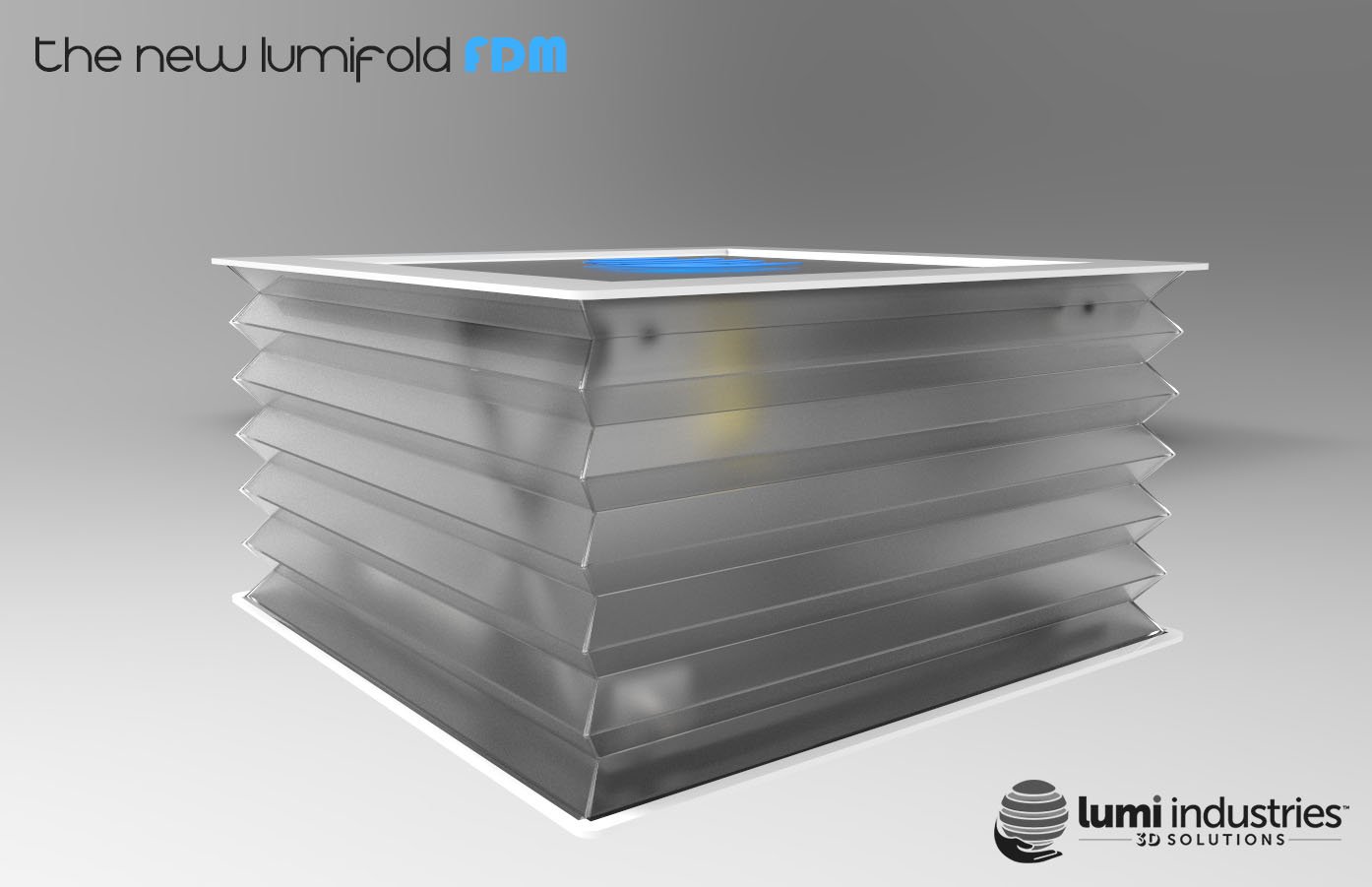

The company believes the new foldable mechanism is applicable for 3D printers of several different processes, beyond just resin 3D printing, as shown at top. They are, for example, working on a way to integrate a plastic extrusion process into something that looks like this:

What’s even stranger is their idea for the New LumiFold “TAB”, which is essentially a resin-based 3D printer that uses a commonly available tablet computer as its light projector.

Here you can see how a tablet could slide into a LumiFold TAB.

Once inserted, printing takes place and the platform gradually rises, expanding the build volume as it goes.

This is quite revolutionary, but we have one question: resins solidify in the presence of UV light, and we’re not certain the tablets actually produce sufficient UV light to do so, as they’re not designed for this purpose. It’s possible layer curing might take longer due to this. [UPDATE: It turns out the TAB will use visible light-curable resin; see details below.]

Also, the TAB will have to protect the resin tank from unwanted UV light from other sources, such as the sun shining through a nearby window. Unlike the concept images, they’ll likely have to include a collapsible shroud around the TAB, similar to what their plastic extrusion concept looks like.

But these are just concepts at this point. For now, they’re working on three machines of their own that integrate this technology: the New LumiFold CUBE, the New LumiFold DLP and the New LumiFold XL.

The CUBE unit holds a small build volume of 100 x 100 x 50mm and could be the ideal portable resin 3D printer, while the DLP unit is larger at 150 x 150 x 150mm and can use a wider variety of resins. The XL is even larger at 250 x 350 x 300mm, which is perhaps the largest volume portable 3D printer you might find.

Finally, the company is also developing the “New LumiFold FDM” machine, which uses the same scissor mechanism for portability while employing a plastic extrusion toolhead. As Lumi Industries is expert at developing resin 3D printers, they are seeking a partner to create a plastic extrusion mechanism with them.

They don’t say who that partner is, but we can tell you that “FDM” is a registered trademark of Stratasys and cannot be used by others without license. If Lumi Industries has named their machine after this trademark, it’s possible they have partnered with Stratasys on this venture.

Or not, in which case they’d best change the machine name pronto!

[UPDATE] Lumi Industries CEO Davide Marin contacted us with some clarifications. The TAB concept will not use UV-curable resins, but instead use visible light-curable resins, which are easily provided by any tablet computer. Using visible light increases the importance of shielding the build chamber from ambient light, which Marin explains will definitely be done – the TAB concept illustrations above do not show the shield to better explain the printing concept, but they will definitely be part of the final configuration. Meanwhile, the CUBE and DLP versions will use UV-curable resins.

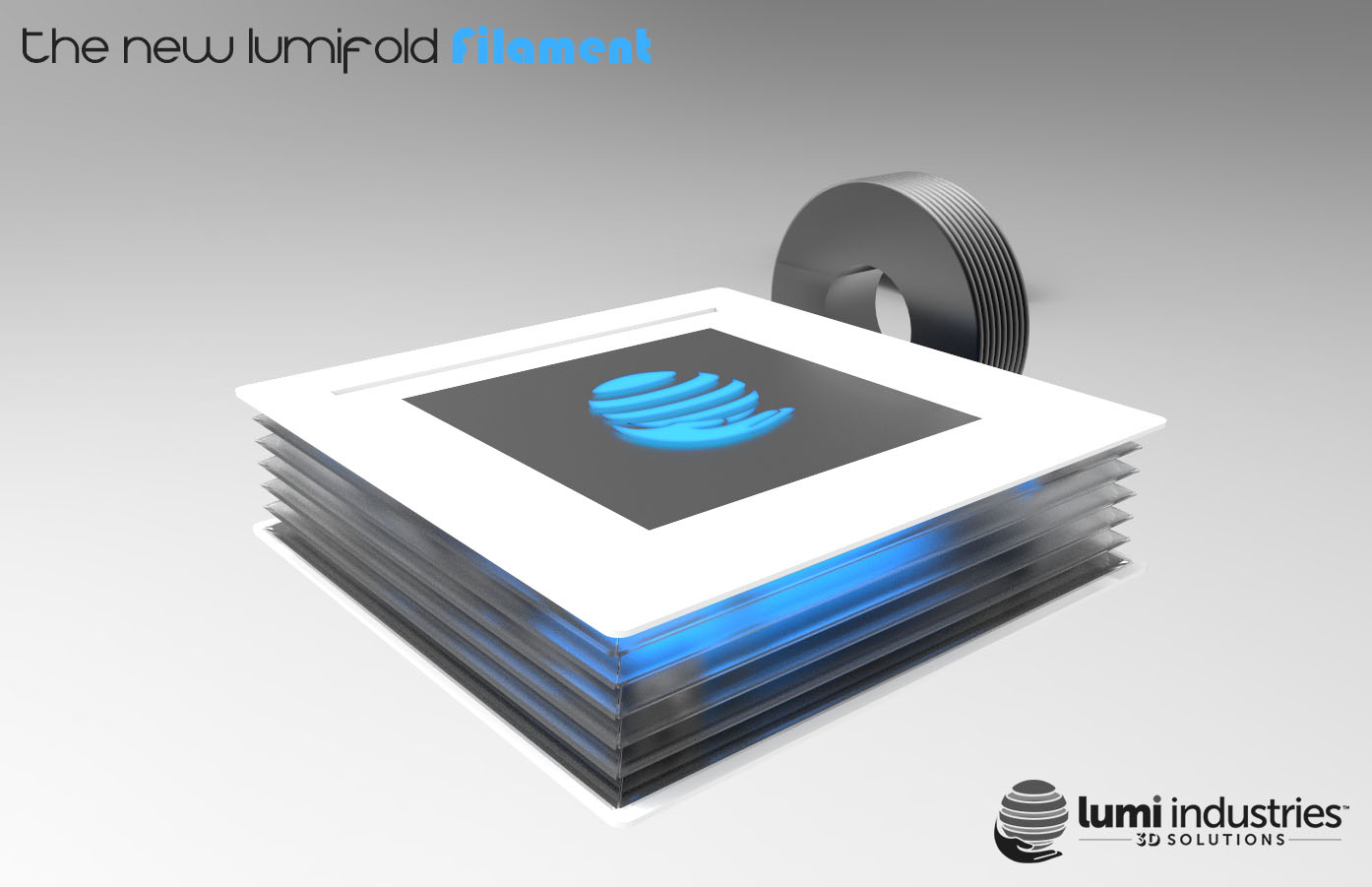

Finally, Marin has issued a new concept for the filament-extrusion version of the LumiFold concept, now called the “New LumiFold Filament”, shown here. Good choice!

Via Lumi Industries