If you are like us, you would have been watching SpaceX unveil their astonishing new spacecraft, the Dragon V2.

It’s SpaceX’s first human-rated ship, which they intend to use for ground-to-low-orbit transfers. Seating seven, the ship’s interior is, beyond any doubt, suitable for any science fiction setting. Except it’s a real spaceship.

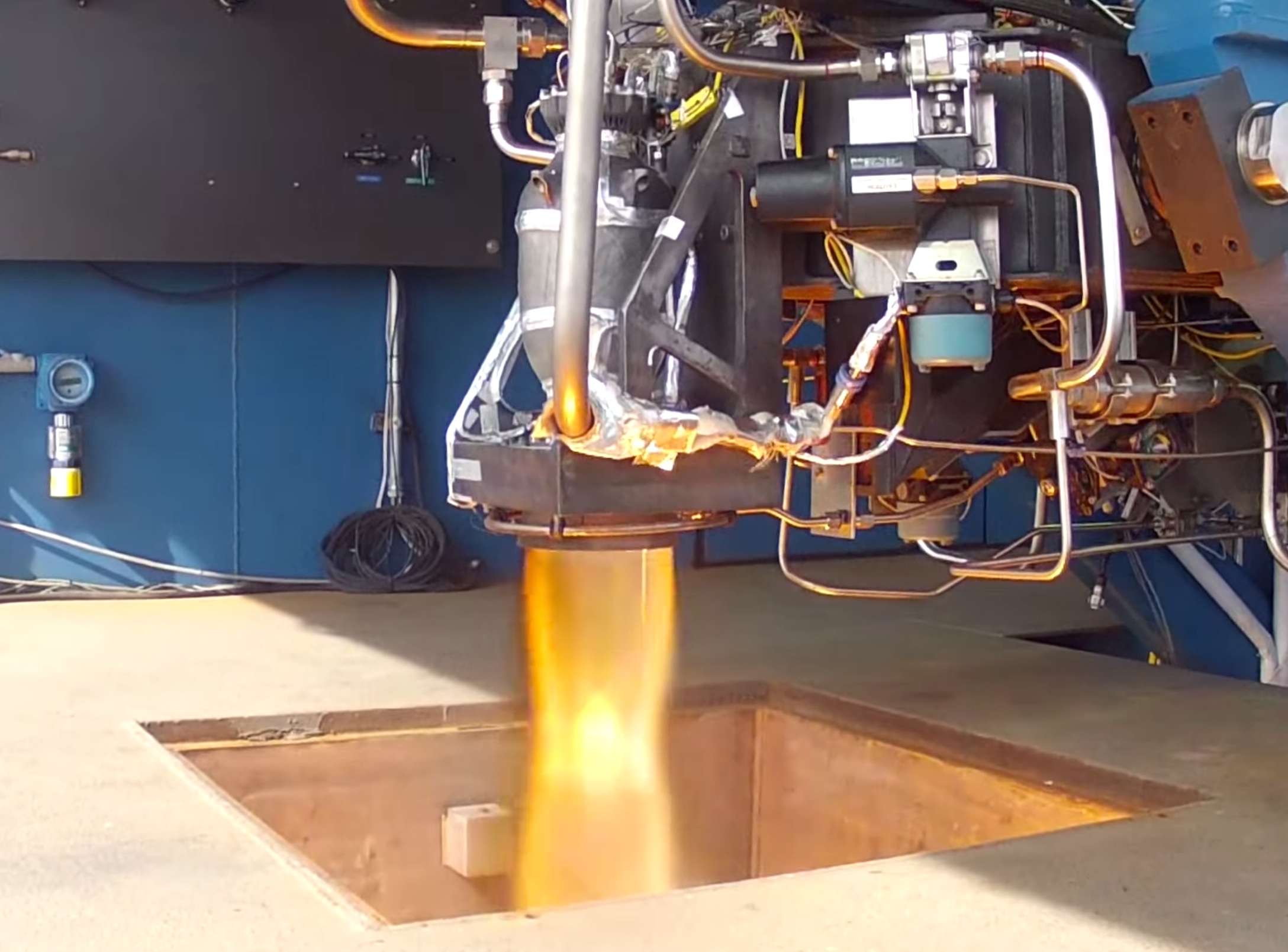

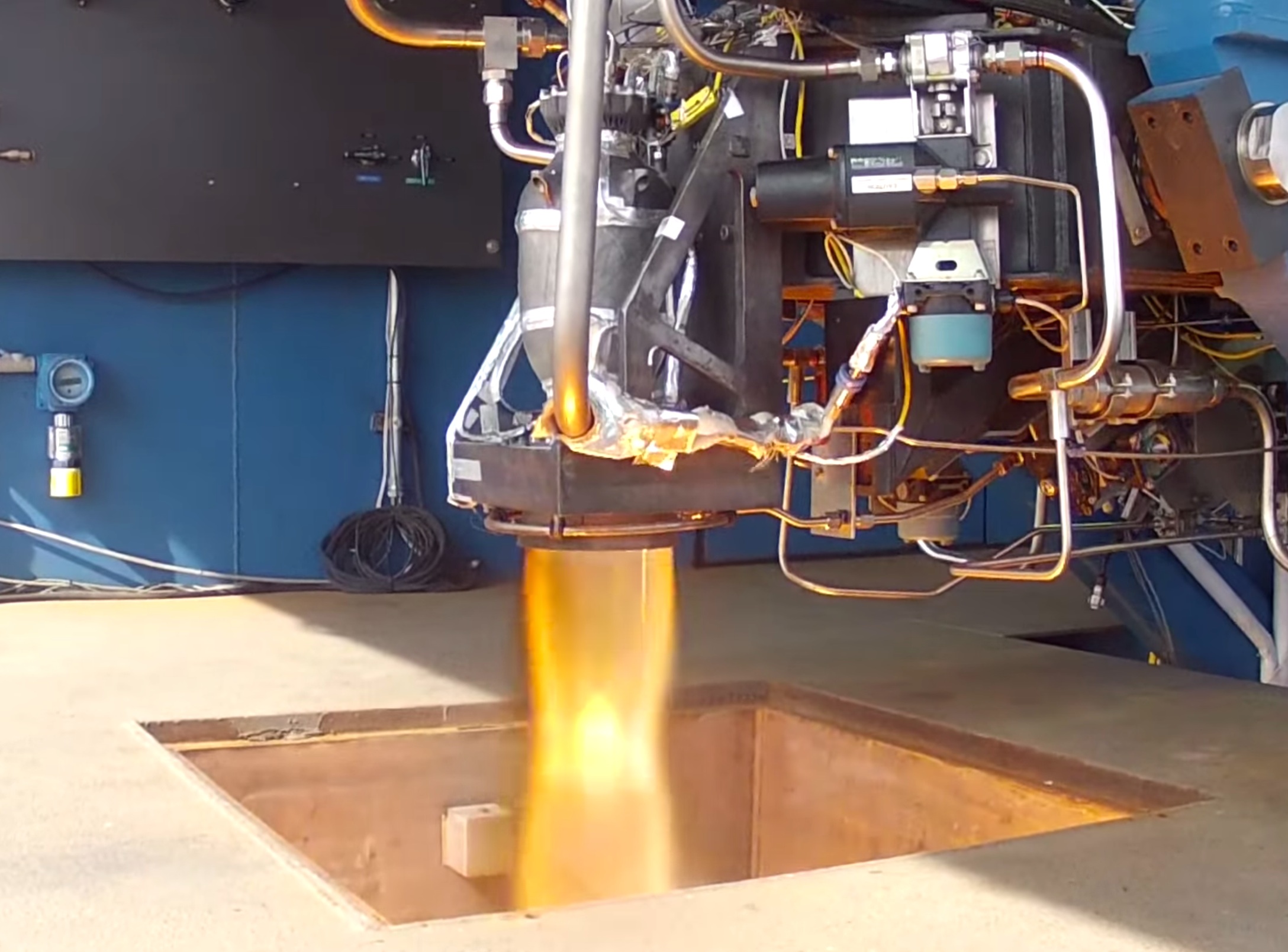

One of the Dragon V2’s features is the ability to land the capsule using an array of embedded rocket engines, as well as for a quick exit in case of emergency during launch. The SuperDraco thruster engine will be used in pairs for redundancy.

But here’s the thing: the thrusters are 3D printed in metal. SpaceX says:

The SuperDraco engine chamber is manufactured using state-of-the-art direct metal laser sintering (DMLS), otherwise known as 3D printing. The chamber is regeneratively cooled and printed in Inconel, a high-performance superalloy that offers both high strength and toughness for increased reliability.

There’s one thing they didn’t say: They believe so strongly in the reliability of 3D printing that they’d bet their lives on it.

Via SpaceX