The folks at intentional3D have managed to acquire a new MakerBot fifth generation Replicator and performed a tear down on the fancy new “Smart” extruder.

They wanted to find out how the component is able to prevent filament jams and generally see how difficult it would be to repair it if required. Among the discoveries:

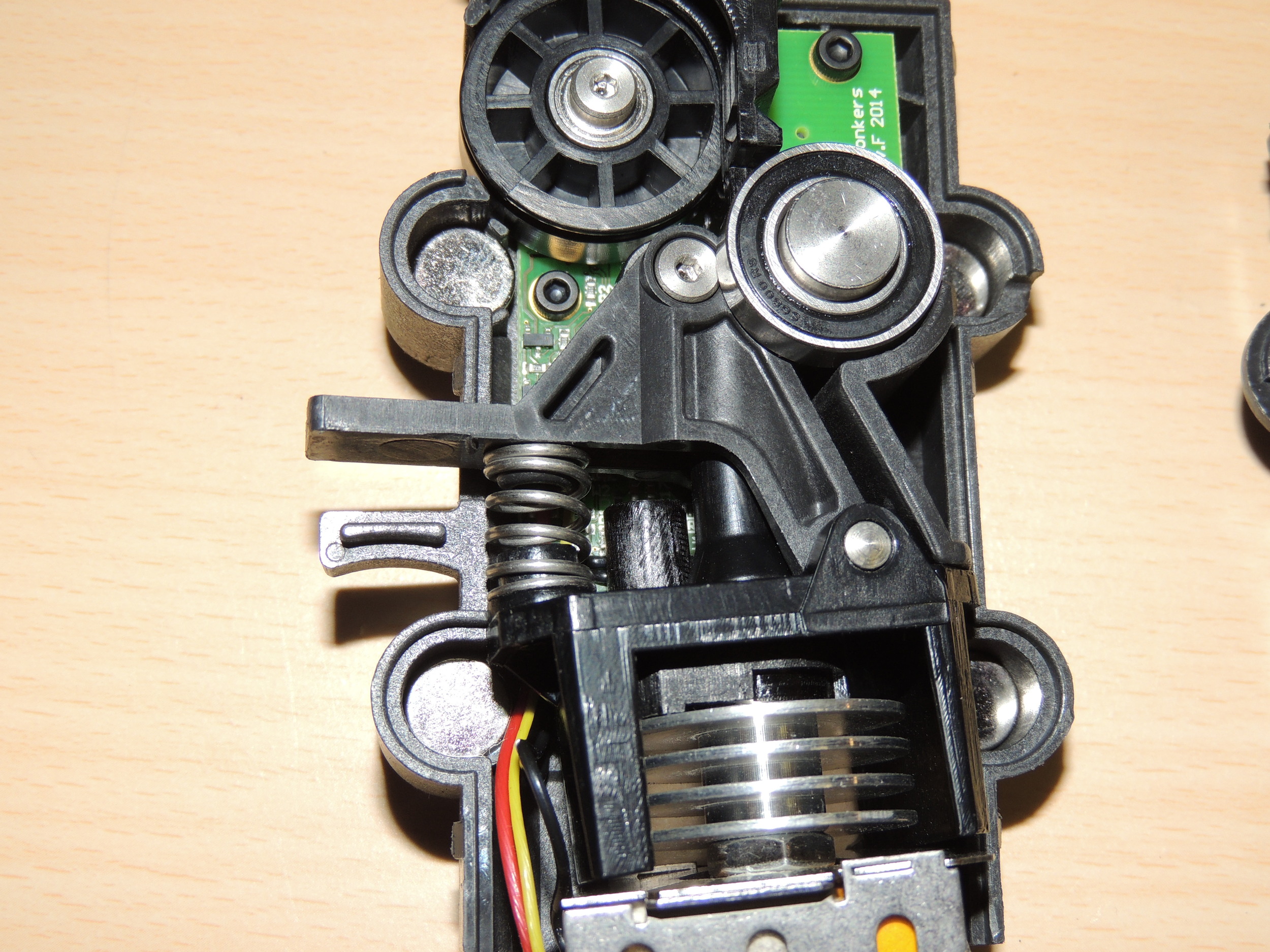

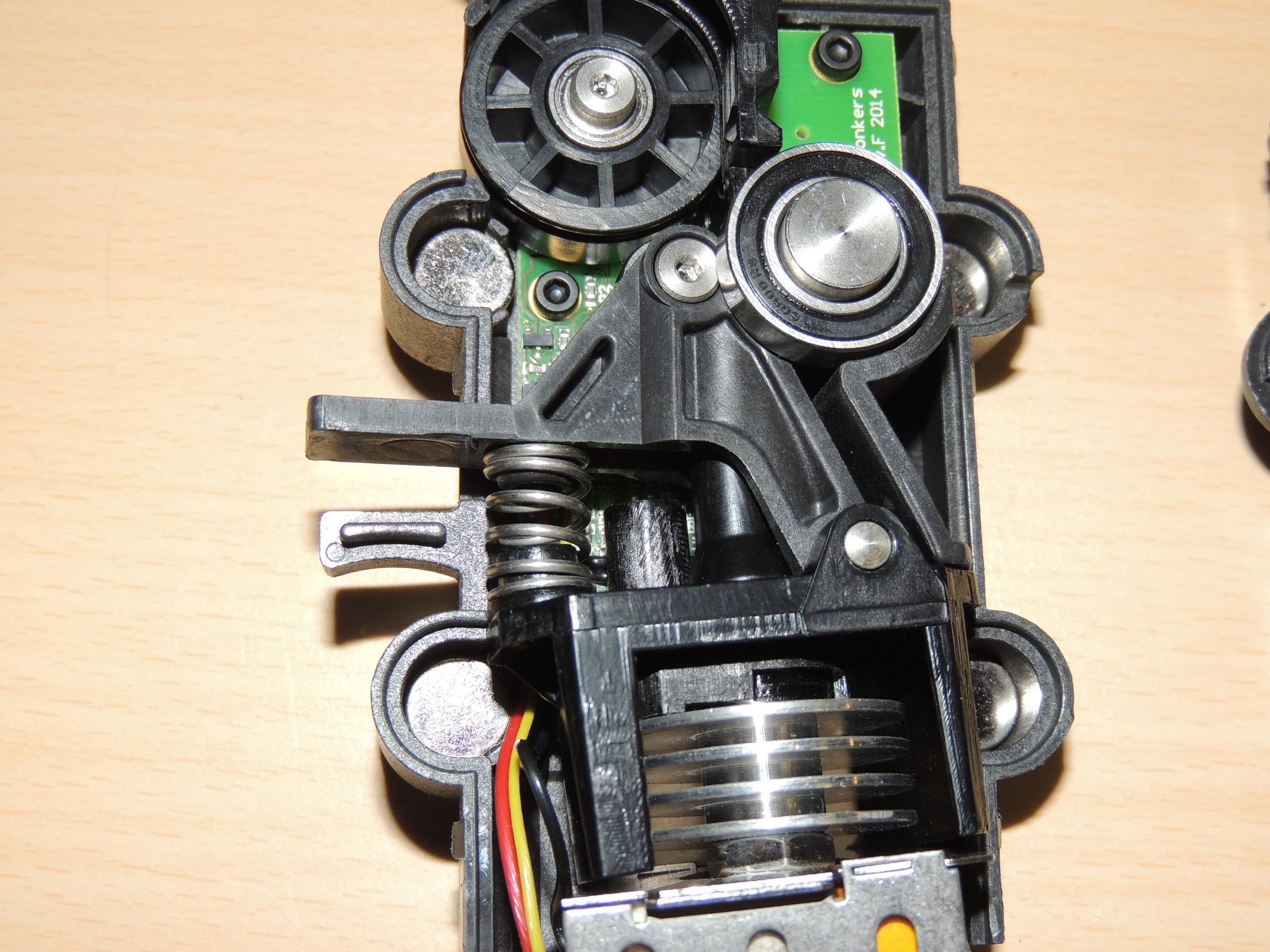

- A cylindrical tube was originally intended to be the filament input route, but MakerBot apparently decided not to use it at the last minute due, as the “sharp turn” could snap the filament.

- The extruder is truly an aggregation of all the discoveries MakerBot and others have made in the past few years.

- A hidden magnet performs an unknown mechanical function, perhaps related to stabilizing the extruder’s movements.

- A tiny circuit board at the top includes a switch that is used to detect whether filament is present.

- A sensor towards the bottom detects whether filament is actually feeding. This means software can intelligently detect and manage several common filament problems.

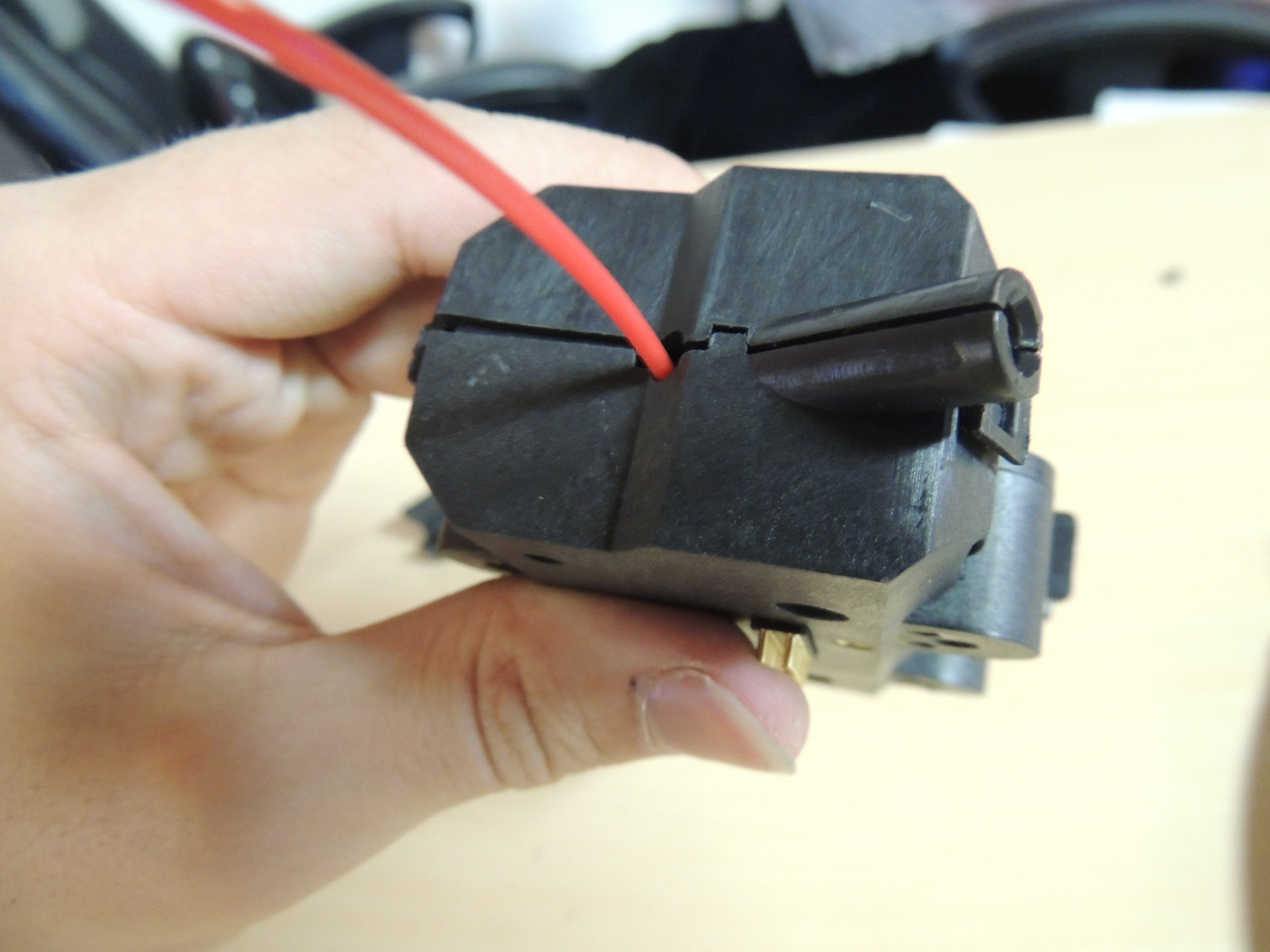

- It is possible to disassemble and successfully reassemble the Smart extruder.

Given the filament problems we’ve seen on almost every plastic extrusion 3D printer, it’s no wonder MakerBot calls this component their “Smart Extruder”.

Via Intentional3D