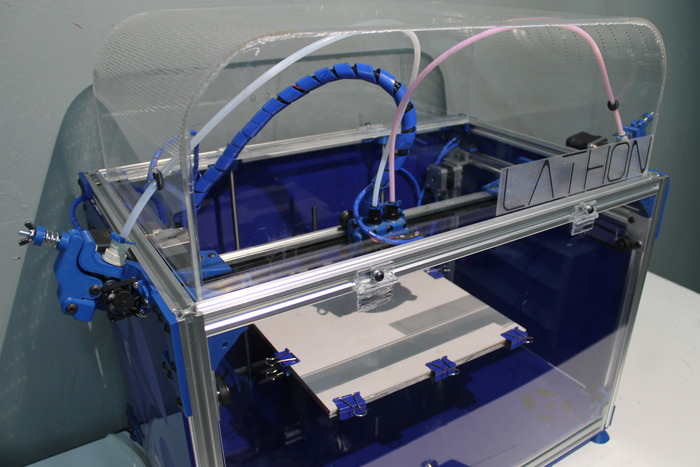

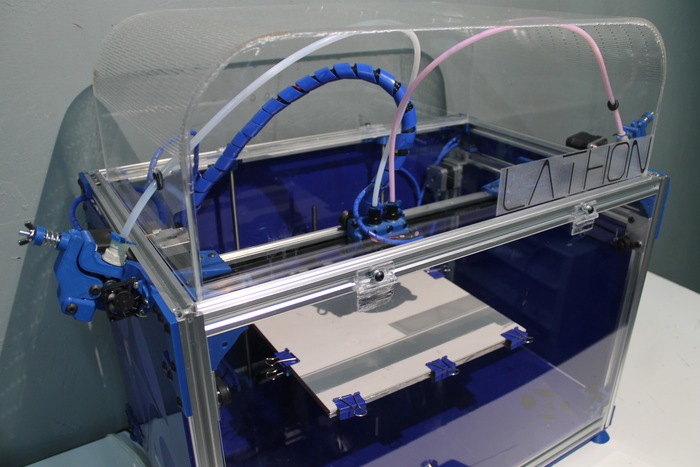

Another 3D printer has appeared on Kickstarter, but we think the Lathon 3D printer has features you simply won’t find in other machines.

The Lathon, designed by Nohtal Alex Partansky of Atlanta, includes the usual features, such as dual bowden-style extruders, ability to print a variety of filament materials, standalone SD-card operation, LCD panel and even a very generous build volume of 305 x 230 x 205mm. But we found several interesting features that are only offered rarely or not at all on other machines.

The Lathon provides a completely enclosed build chamber, which enables much more reliable 3D printing of ABS and other plastics that warp when cooled. The machine’s heated bed will by implication warm up the build chamber just enough.

The print bed is made of ULTEM. While the latest trend has been to use glass or aluminum as a rigid print bed surface, ULTEM is quite different. It’s a plastic, but it has a very high temperature melting point, far above any temperatures used by the extruders. What make it interesting is that you won’t require any special tricks to make your print stick to the bed:

The printing surface is made out of Ultem 2300 that does not need any tape or ABS juice to function. Laminating kapton tape to the build surface takes at least 5-10 minutes and applying ABS juice is messy; this will not be a problem for any of the LATHON users. Just use the included heated bed, let the print cool down and the final print simply pops right off.

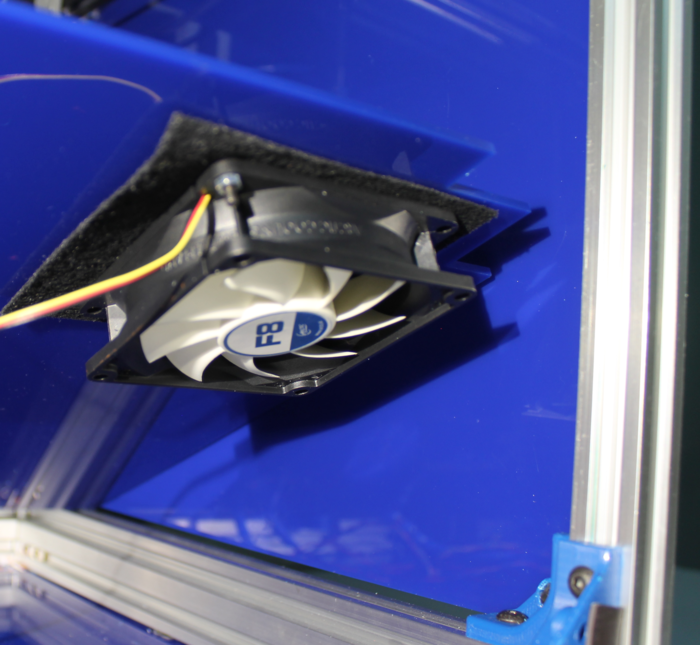

The one feature we really like is the included air filtration. The Lathon’s build chamber is evacuated by a fan equipped with “activated carbon filters” to “drastically reduce the amount of ABS particles in the air”. Finally! We believe EVERY 3D printer should have this feature. Hopefully the filter can catch nano particles, too.

The project’s goal is to raise USD$80,000 and they’re partway there. If you’d like to consider a large personal 3D printer with some great features, check out the Lathon.

Via Kickstarter