Yesterday as CES 2014 opened we had to drop by the 3D Systems booth as they had just that morning released information on multiple new products and services. It’s not the old days when one or perhaps two products appear; today they arrive in batches.

We were toured through the new products by a very excited 3D Systems CEO Avi Reichental, who was and is genuinely proud of the set of innovations his company unleashed on the 3D printing world this week.

Like MakerBot’s release of multiple products the previous day, we are only able to merely summarize the announcements today. All deserve a deeper look, and two in particular require significant analysis.

What was announced? Let’s take a look:

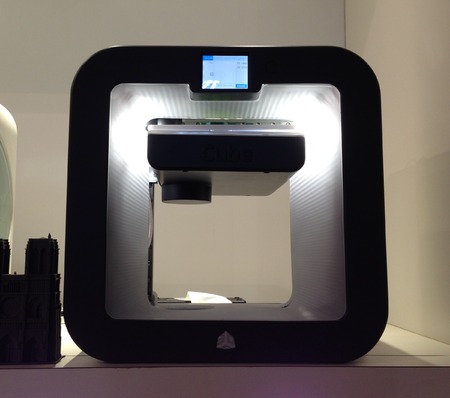

A vastly improved version of their entry-level personal 3D printer, the Cube. Aside from the much more attractive styling, this unit now includes TWO extruders. We observed several units printing multicolored objects with them. We also learned the new Cube has a never-need-to-level print platform. Reichental describes the platform as “very clever”, while we would say “finally!” Why should leveling ever be required? It will never happen again if you have a new Cube, either a black or white unit.

The Cube also includes brand new side-mounted filament cartridges that have a foolproof loading procedure that completely eliminates manual threading. The audiojack-like filament holder is simply pushed in and given a quarter turn. Even better, the new cartridge is powered from the spool’s hub – the PLA or ABS filament is NOT pulled, it is PUSHED. We expect to have far fewer incidents of broken filament with this cartridge. Another incredible feature is the resolution; this Cube can print layers as small as 0.075mm. Oh, one more thing: the price of this unit will be less than USD$1000. For a fully-assembled, dual extruder device!

The one-year old CubeX appears to be have been replaced by the CubePro. Externally this unit seems quite different from the prior model, as its new case matches the now-standard style of 3D Systems devices. We were curious about the innards and took a quick look inside. While we were not permitted to take any images of the interior, a quick glance showed few if any differences from the original CubeX. Reichental indicated the machine has a sealed build chamber, leading to more reliable and less warpy prints with its “Controlled Print Environment”. Even better, the CubePro can now print in 0.075mm layers for even finer results.

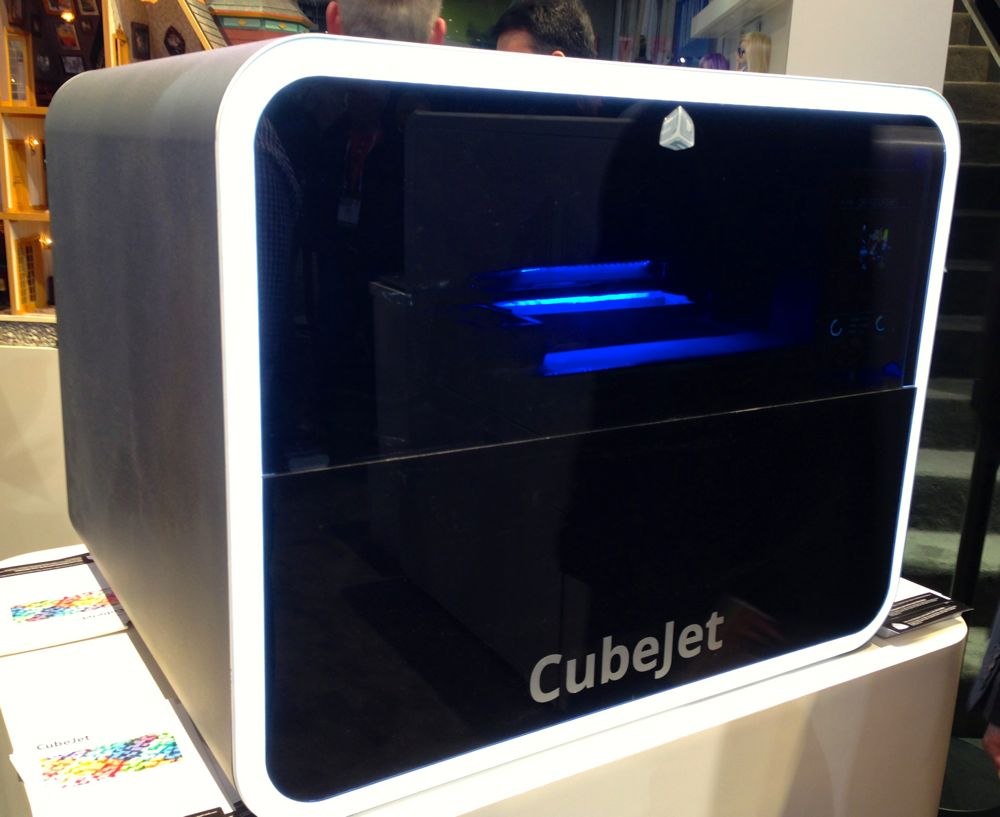

The CubeJet is another amazing innovation. 3D Systems has taken their ZCorp-originated technology and adapted it for a very low-priced entry-level full RGB color 3D printer. Yes – you can actually print full color objects with this unit for less than USD$10K, although it will become available for purchase later this year.

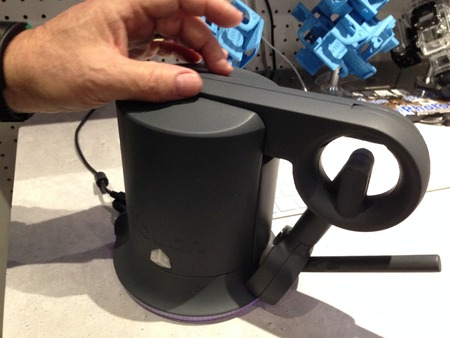

The Touch is a haptic-enabled 3D mouse for “intuitive 3D sculpting” using 3D Systems’ Cubify Sculpt software. The mouse can be moved in 3 dimensions as if you were physically sculpting in clay. The difference is that the device provides force-feedback as you bump into solid surfaces in your design. We’re hoping to test this USD$499 (with included software) device soon.

A completely surprising announcement was the release of the CeraJet – a 3D Ceramic printer. The CeraJet is a powder-based device that uses, not surprisingly, a proprietary ceramic powder and liquid binder. Like other powder 3D printers, the CeraJet gradually builds the object layer by layer.

Once complete it is removed from the powder-filled build chamber and a traditional firing and glazing process proceeds from there. We inspected sample output and found them to be indistinguishable from normal ceramics – with the exception being the intricate designs possible only with 3D modeling software. The CeraJet is set to be delivered in the second half of 2013.

The ChefJet and ChefJet Pro are real, no-foolin 3D FOOD PRINTERS! The ChefJets are a commercialized version of the technology 3D Systems obtained with their acquisition of The Sugar Lab. The base model is suitable for use in kitchens and is entirely food safe. It can print edible 3D models in “sugar, chocolate or candy with an added single flavor”.

We were able to sample the somewhat fragile ChefJet output and were surprised at not only the taste, but the texture. You’ve never eaten candy quite like this; it is very light and almost instantly melts in your mouth. Reichental confirmed our suspicion that 3D Systems now has official food scientists on staff who successfully worked this out.

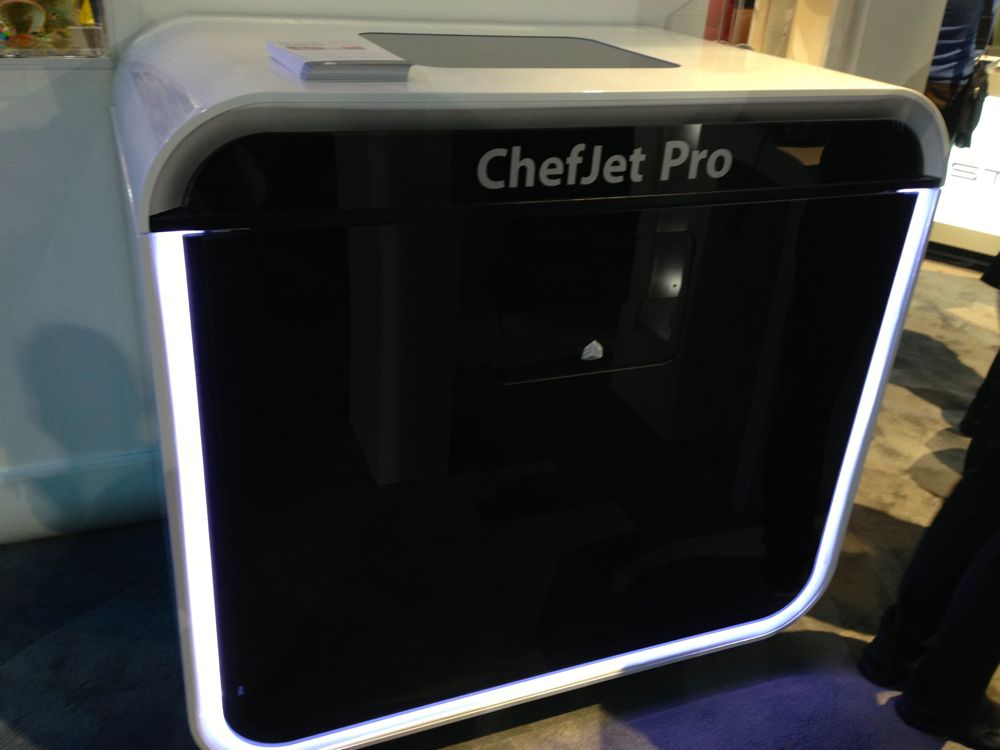

The ChefJet Pro is a much larger machine that’s intended for use by professional kitchens. It also prints in sugar using a powder process, but has the added ability to print in FULL COLOR!

We inspected several awesome edible 3D food prints emblazoned with brilliant colors. With such a machine in the kitchen, a 3D-minded chef could produce unimaginable cake toppers, displays or desserts. Of all the innovations from 3D Systems, this one has the most open-ended future. Both ChefJets should be available for purchase later in 2014.

You probably won’t believe us, but there were even MORE announcements of other incredible products and a slew of new 3D services. Stay tuned for another post to describe them.

Meanwhile, the two announcements we thought of most significance are, of course, the CeraJet and the ChefJets because they are not only new 3D printers, but in fact create not one, but TWO entirely new categories of commercial 3D printers, available to anyone: Food and Ceramics. It’s very clear why Reichental is so excited.

3D printing will never be the same. Yum!

Via 3D Systems