The traditional process for making plastic parts is to first create a metal mold into which hot plastic is injected. After the plastic cools, remove the mold and you have your plastic part. This is called, “injection molding”.

People owning a 3D printer have wondered how to print a injection-capable mold, but it’s obviously problematic to inject hot plastic into a mold made of the same plastic.

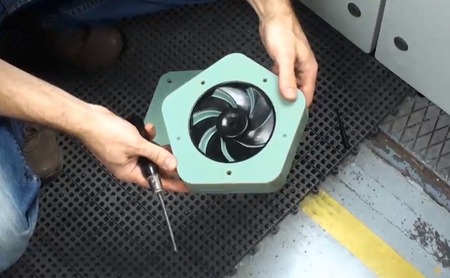

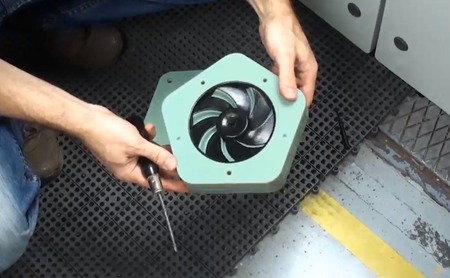

Stratasys solved this problem through the use of ingenious 3D print materials on their Objet Connex commercial 3D printer. As you’ll see in this short video, they are able to directly 3D print and use an injection mold with their digital ABS material.

In the video you’ll see they place the 3D printed mold in an Arbug injection molding machine, subjecting the mold to 210C temperatures, 300 bar injection pressure and 150 kilnewtons of holding pressure to keep the hold in one piece during the process. The plastic injected was Polyoxymethylene (POM), also known as Delrin and other brand names.

This is a huge step forward, simply because of cost advantages. The price to produce a traditional metal injection mold is can easily be in the tens of thousands of dollars, if not more. By simply 3D printing them, many companies are set to save a great deal of money.

Via Stratasys