Researchers Collin Ladd, Ju-Hee So, John Muth and Michael D. Dickey at NC State University have published a paper describing their experiment in 3D printing liquid metal – at room temperature.

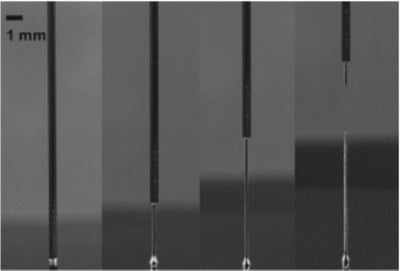

The liquid metal used by the researchers is binary eutectic alloy of gallium and indium, which, in very small droplet form becomes relatively stable as you can see in the video below. They’ve been able to 3D print microstructures, wires and interconnects with this new approach.

The structures formed are soft and flexible, making the technique suitable for building microelectronics. Four extrusion techniques were successfully demonstrated:

- Extruded wire

- Stacked droplets to form arbitrary structures

- Molding within channels

- Jetting out a filament structure

The structures produce are electrically conductive and are capable of acting in electric circuits.

This is a major development. Previous attempts at printing electric circuits have proven difficult, particularly at micro-scale. This technology could theoretically be easily added to a conventional 3D printer enabling the production of objects with embedded electric circuits.

And then everything changes.

Via Wiley