You heard the rumors, as did we. Formlabs has been working on a top secret “revolutionary” personal 3D printer and today it’s unveiled for your consideration. We consider the new Form 1 3D printer to be a very important step in the development of personal 3D printing, and something you’ll want to check out.

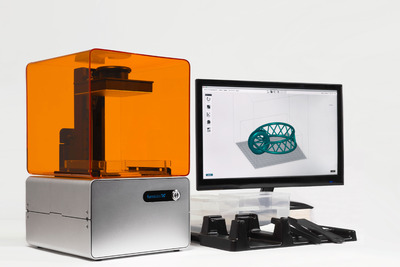

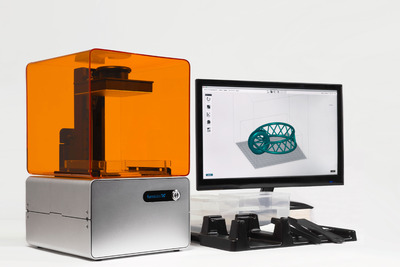

You heard the rumors, as did we. Formlabs has been working on a top secret “revolutionary” personal 3D printer and today it’s unveiled for your consideration. We consider the new Form 1 3D printer to be a very important step in the development of personal 3D printing, and something you’ll want to check out.The Form 1 is a resin-based 3D printer. It does not use fused plastic filament as do most other personal 3D printers; instead it uses photo-cured resin to build amazingly detailed objects, creating complete layers in a single operation. We don’t yet know the speed of the Form 1, but it’s likely very fast compared to conventional plastic filament 3D printers.

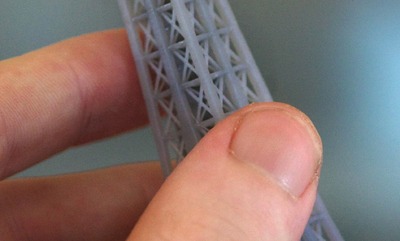

The build envelope of the form 1 is not particularly large at 125 x 125 x 165mm (4.9 x 4.9 x 6.5 inches). Nevertheless, the Form 1 definitely shines in the resolution department: layers can be as small as an astonishing 25 microns, or 0.025mm. This is as 10-20x better than typical personal 3D printers, and even 4x better than MakerBot’s latest super-high resolution Replicator 2. Don’t believe us? Take a look at these near-unbelievable images of Form 1 output (click for larger view).

The build envelope of the form 1 is not particularly large at 125 x 125 x 165mm (4.9 x 4.9 x 6.5 inches). Nevertheless, the Form 1 definitely shines in the resolution department: layers can be as small as an astonishing 25 microns, or 0.025mm. This is as 10-20x better than typical personal 3D printers, and even 4x better than MakerBot’s latest super-high resolution Replicator 2. Don’t believe us? Take a look at these near-unbelievable images of Form 1 output (click for larger view).  Check out the startling difference between typical plastic filament 3D prints on the left versus objects produced by the Form 1’s resin process. (Click for larger view)

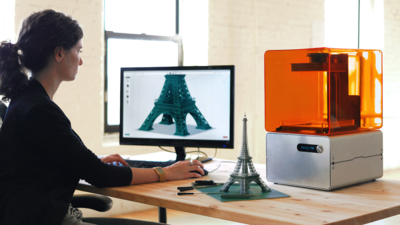

Check out the startling difference between typical plastic filament 3D prints on the left versus objects produced by the Form 1’s resin process. (Click for larger view)The team behind Formlabs is a trio of recent MIT grads, Maxim Lobovsky, David Cranor, and Natan Linder, who felt there could be a better way for personal 3D printer owners to obtain super-high quality prints.

There have been several other attempts at launching an inexpensive resin-based 3D printer recently, but few seem to have as much momentum as Formlabs, who have significant investors behind them.

The Form 1 will be pre-sold as a Kickstarter project, as is rapidly becoming customary for those launching new 3D printer projects. The price? US$2,299. The project hopes to raise USD$100,000, and we suspect they’ll hit that very quickly. Your contribution will get you not only the Form 1 3D printer, but also a convenient “Form Finish” station and easy-to-use software.

The Form 1 will be pre-sold as a Kickstarter project, as is rapidly becoming customary for those launching new 3D printer projects. The price? US$2,299. The project hopes to raise USD$100,000, and we suspect they’ll hit that very quickly. Your contribution will get you not only the Form 1 3D printer, but also a convenient “Form Finish” station and easy-to-use software.Via Formlabs and Kickstarter

I've used stereolithography in the past, and it certainly is one of the gold standards for resolution. However, its strength lies in prototyping. The resin used isn't nearly as strong as ABS or even PLA (which Makerbot, et al uses). ABS pieces, while less accurate, are meant to be used right out of the printer. Still, the precision cannot be denied.

What it boils down to is . . . what are you trying to make? If you want a 3d printer to make a part for immediate use (ABS/PLA), then Form 1 isn't even looking at you. It is for someone who wants to PROTOTYPE a piece. Honestly, despite the fantastic precision, stereolithography means Form 1 is aiming for a different user than the Makerbot guys.

Either way, the fact that there are more and more 'low cost' consumer 3d printers starting to appear is fantastic. If you've got the money, and need an SL printer, you owe it to yourself to AT LEAST look at the Form 1.

I've used stereolithography in the past, and it certainly is one of the gold standards for resolution. However, its strength lies in prototyping. The resin used isn't nearly as strong as ABS or even PLA (which Makerbot, et al uses). ABS pieces, while less accurate, are meant to be used right out of the printer. Still, the precision cannot be denied.

What it boils down to is . . . what are you trying to make? If you want a 3d printer to make a part for immediate use (ABS/PLA), then Form 1 isn't even looking at you. It is for someone who wants to PROTOTYPE a piece. Honestly, despite the fantastic precision, stereolithography means Form 1 is aiming for a different user than the Makerbot guys.

Either way, the fact that there are more and more 'low cost' consumer 3d printers starting to appear is fantastic. If you've got the money, and need an SL printer, you owe it to yourself to AT LEAST look at the Form 1.